Table of Contents

Centrifugal Pump

A centrifugal pump is a machine that uses the centrifugal force to move fluids. It is a type of dynamic or kinetic pump that converts mechanical energy into fluid energy.

The pump consists of a rotating impeller that creates a centrifugal force to increase the pressure of the fluid and move it through the pump.

The impeller is usually made of metal or plastic and has curved blades that spin around a central shaft. As the impeller rotates, the blades accelerate the fluid, causing it to move outwards towards the edges of the impeller.

The fluid then exits the impeller through a volute or diffuser, which is a specially designed casing that converts the kinetic energy of the fluid into pressure.

Centrifugal pumps are commonly used in industrial, commercial, and residential settings to transport fluids such as water, chemicals, and petroleum products.

They are preferred over other types of pumps because of their simplicity, low maintenance requirements, and high flow rates. However, they may not be suitable for pumping high-viscosity fluids or for applications that require high pressure or suction lift.

What is Centrifugal Force?

Centrifugal force is a fictitious or apparent force that arises in a non-inertial reference frame when an object moves in a circular path. It is an outward force that appears to act on an object moving in a circular path, away from the center of the circle.

In reality, there is no actual force pushing the object outwards. Instead, the object’s inertia causes it to resist changes in direction and maintain a circular path. The apparent force that arises is simply a result of the observer’s perspective, as they are viewing the object’s motion from a rotating reference frame.

Centrifugal force is often confused with centripetal force, which is the actual force that keeps an object moving in a circular path. Centripetal force is directed towards the center of the circle, while centrifugal force appears to act in the opposite direction, away from the center of the circle. Both forces are necessary to maintain circular motion.

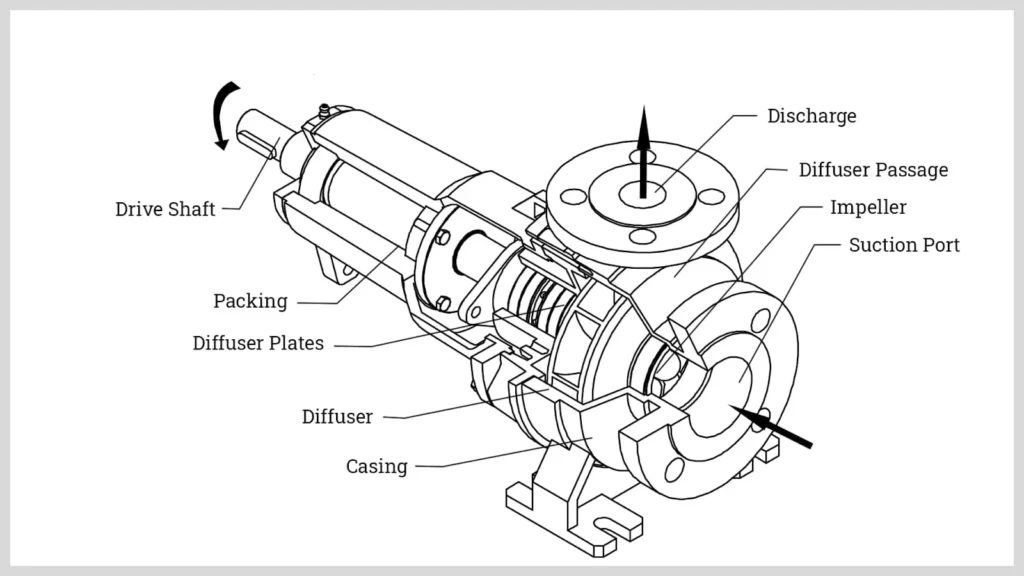

Main Parts of Centrifugal Pump

The main parts of a centrifugal pump include:

Impeller: The impeller is a rotating component of the pump that generates the centrifugal force required to move the fluid. It consists of blades or vanes that are curved to direct the flow of the fluid.

Casing: The casing is a stationary component of the pump that surrounds the impeller and provides a passage for the fluid to flow through. It is designed to convert the kinetic energy generated by the impeller into pressure energy.

Shaft: The shaft connects the impeller to the motor and transmits the power required to drive the pump.

Bearings: Bearings support the shaft and reduce friction between the rotating and stationary components of the pump.

Seal: The seal prevents fluid from leaking out of the pump along the shaft.

Suction and discharge connections: These connections allow the fluid to enter and exit the pump.

Drive motor: The motor provides the power required to rotate the impeller.

Coupling: The coupling connects the motor and the pump shaft, allowing the motor to transfer power to the impeller.

Centrifugal pumps may also include additional components such as a volute, which is a spiral-shaped casing that helps to balance the fluid pressure as it exits the pump, and an inlet strainer, which prevents debris from entering the pump.

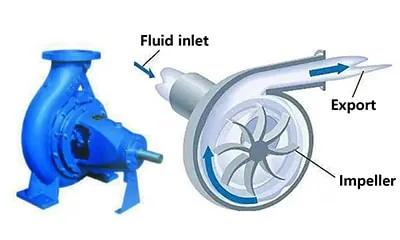

Working principle of centrifugal pump

The working principle of a centrifugal pump is based on the transfer of mechanical energy from a rotating impeller to the fluid being pumped. The impeller is a rotating component that consists of blades or vanes that move the fluid by creating a centrifugal force.

When the impeller rotates, it creates a low-pressure zone at the center and a high-pressure zone at the outer edges of the impeller. The fluid is drawn into the low-pressure zone and then pushed outward by the high-pressure zone, causing the fluid to move radially outward.

The fluid then enters the volute casing, which is a stationary component surrounding the impeller. The volute casing converts the kinetic energy of the fluid into pressure energy by gradually increasing the cross-sectional area of the casing. As the fluid flows through the volute casing, its velocity decreases and the pressure increases.

The fluid is then discharged through the pump’s outlet, where it can be sent to its intended destination. The pump’s performance is determined by various factors, such as the impeller diameter, the speed of rotation, and the design of the volute casing.

Overall, the centrifugal pump works by using the rotation of an impeller to create a centrifugal force that moves the fluid being pumped through the system. This simple and effective design has made centrifugal pumps widely used in many different industries and applications.

Working of Centrifugal Pump

The working principle of a centrifugal pump involves the transfer of mechanical energy from a motor to a rotating impeller, which creates a flow of fluid in the pump. The basic working steps are as follows:

The pump is first primed, which means that the fluid to be pumped is introduced into the pump’s casing and impeller.

The impeller is rotated by the motor, which creates a centrifugal force that propels the fluid towards the edge of the impeller.

As the fluid is pushed outwards by the impeller, it is directed towards the volute, which is a specially designed casing that converts the kinetic energy of the fluid into pressure energy.

The pressure energy created by the volute causes the fluid to exit the pump through the discharge outlet.

At the same time, fluid is drawn into the pump through the inlet due to the low pressure created by the rotation of the impeller.

This process continues as long as the pump is in operation, with fluid being continuously drawn into the pump and discharged out through the outlet.

Overall, the working of a centrifugal pump relies on the conversion of mechanical energy into fluid energy through the use of a rotating impeller and a specially designed casing. The impeller creates a flow of fluid, and the casing converts the kinetic energy of the fluid into pressure energy, which allows the fluid to be moved through the pump and into a pipeline or other system.

Types of Centrifugal Pumps

There are several types of centrifugal pumps, each with its own specific design and application. Some common types of centrifugal pumps include:

End-suction pumps: These pumps have a horizontal shaft and a single impeller that is located at the end of the shaft. They are typically used for water supply, heating and cooling systems, and general industrial applications.

Split-case pumps: These pumps have a horizontal shaft and a double-suction impeller that is split in half. They are often used for high-flow and high-pressure applications, such as water supply for cities or irrigation systems.

Vertical inline pumps: These pumps have a vertical shaft and a single-stage impeller that is mounted in a casing. They are commonly used for HVAC systems, water supply, and fire protection.

Multi-stage pumps: These pumps have multiple impellers arranged in a series along a single shaft. They are used for applications that require high pressure, such as water treatment, boiler feed, and petroleum refining.

Self-priming pumps: These pumps are designed to automatically prime themselves without the need for external priming. They are often used for sewage and wastewater applications.

Submersible pumps: These pumps are designed to be submerged in the fluid that they are pumping. They are commonly used for applications such as drainage, sewage pumping, and deep well pumping.

What are the main features of a centrifugal pump

The main features of a centrifugal pump are as follows:

Impeller: The impeller is the primary component of a centrifugal pump and is responsible for generating the fluid flow. It is typically made of metal or plastic and consists of curved blades that rotate to create a centrifugal force.

Casing: The casing is a stationary component that surrounds the impeller and provides a channel for the fluid to flow through. It is typically made of metal or plastic and is designed to convert the kinetic energy generated by the impeller into pressure energy.

Shaft: The shaft connects the impeller to the motor and transmits the power required to drive the pump. It is typically made of steel or other strong materials.

Bearings: Bearings are used to support the shaft and reduce friction between the rotating and stationary components of the pump. They are typically made of metal or plastic and may require lubrication to prevent wear and tear.

Seals: Seals are used to prevent fluid from leaking out of the pump along the shaft. There are several types of seals, including mechanical seals, packing seals, and lip seals.

Inlet and outlet connections: The inlet and outlet connections allow the fluid to enter and exit the pump. They are typically made of metal or plastic and may be threaded, flanged, or otherwise secured to the pump casing.

Motor: The motor provides the power required to drive the pump. It may be electric or powered by another energy source, such as diesel or gasoline.

Overall, the main features of a centrifugal pump are designed to generate a flow of fluid and convert kinetic energy into pressure energy, while minimizing friction, leaks, and other potential sources of inefficiency.

Type of casing in centrifugal pump

Centrifugal pumps typically have two types of casing: volute casing and diffuser casing.

A volute casing is the most common type of casing used in centrifugal pumps. It consists of a spiral-shaped, stationary casing that is designed to convert the kinetic energy of the fluid exiting the impeller into pressure energy. The volute casing is named after its shape, which resembles a snail’s shell.

A diffuser casing, on the other hand, is a stationary casing that contains a series of stationary vanes that direct the fluid flow into a spiral pattern. The diffuser casing is designed to convert the kinetic energy of the fluid exiting the impeller into pressure energy more efficiently than a volute casing.

Both types of casing are used in centrifugal pumps, and the choice of casing depends on the specific requirements of the application. Volute casings are generally simpler and less expensive, while diffuser casings are more complex and offer higher efficiencies.

Material used for centrifugal pump

The materials used in centrifugal pump parts depend on the specific application and the type of fluid being pumped. However, some common materials used in centrifugal pump parts include:

Cast Iron: This is a common material used for pump casings, impellers, and other parts that are not exposed to corrosive fluids. Cast iron is strong, durable, and relatively inexpensive.

Stainless Steel: This material is commonly used for parts that are exposed to corrosive fluids, such as chemical pumps or seawater pumps. Stainless steel is resistant to corrosion and has good mechanical properties.

Bronze: This material is commonly used for impellers and other parts that are exposed to seawater. Bronze is resistant to corrosion and has good mechanical properties.

Ceramic: This material is used for parts that are exposed to abrasive fluids, such as slurries or wastewater. Ceramic is hard and wear-resistant, making it ideal for such applications.

Carbon Steel: This material is used for parts that are exposed to high temperatures and pressures, such as boiler feed pumps. Carbon steel has good mechanical properties and can withstand high temperatures.

Plastic: Some centrifugal pumps use plastic materials such as polypropylene or PVC for parts that come into contact with corrosive fluids. These materials are resistant to corrosion and are often used in chemical transfer pumps.

Difference Between Reciprocating Pump and Centrifugal Pump

Reciprocating pumps and centrifugal pumps are two different types of pumps used for fluid transfer in various industrial and commercial applications. They operate on different principles and have distinct characteristics.

The key differences between reciprocating pumps and centrifugal pumps

Working Principle:

Reciprocating Pump: It operates on the principle of reciprocation, where a piston or diaphragm moves back and forth inside a cylinder to create a vacuum on one side, drawing in the fluid, and then pressurizing the fluid on the other side to pump it out.

Centrifugal Pump: It operates on the principle of centrifugal force. The pump impeller rotates, creating a centrifugal force that moves the fluid from the center of the impeller to the outer edges, creating a flow of fluid.

Flow Rate:

Reciprocating Pump: Generally, reciprocating pumps have a pulsating or intermittent flow. The flow rate can be adjusted by changing the stroke length, speed, or number of reciprocating elements.

Centrifugal Pump: Centrifugal pumps provide a steady and continuous flow. The flow rate is determined by the impeller diameter and speed.

Pressure:

Reciprocating Pump: Reciprocating pumps are capable of generating high pressures. They are often used in applications where high pressure is required.

Centrifugal Pump: Centrifugal pumps are generally more suitable for applications where moderate to high flow rates are needed but not extremely high pressures.

Efficiency:

Reciprocating Pump: Reciprocating pumps tend to have higher efficiencies at lower flow rates and higher pressures.

Centrifugal Pump: Centrifugal pumps are generally more efficient at higher flow rates but may experience a drop in efficiency at low flow rates.

Maintenance and Wear:

Reciprocating Pump: Reciprocating pumps may have more wear and tear due to the reciprocating motion, requiring more maintenance.

Centrifugal Pump: Centrifugal pumps typically have fewer moving parts and may require less maintenance compared to reciprocating pumps.

Applications:

Reciprocating Pump: Commonly used in applications requiring high-pressure delivery, such as in hydraulic systems, high-pressure cleaning, and some oil and gas applications.

Centrifugal Pump: Widely used in applications like water supply, irrigation, HVAC systems, and industries where a continuous flow at moderate to high rates is needed.

In summary, the choice between a reciprocating pump and a centrifugal pump depends on the specific requirements of the application, such as flow rate, pressure, and the nature of the fluid being pumped.

Limitations of a centrifugal pump

While centrifugal pumps are widely used in many industries and applications, they do have some limitations. Some of the main limitations of centrifugal pumps are as follows:

Low viscosity fluids: Centrifugal pumps are most effective with low viscosity fluids, such as water or thin oils. They may not be as effective with thicker fluids or materials with high levels of solids, such as slurries or wastewater.

Limited suction lift: Centrifugal pumps have a limited ability to lift fluids from a lower elevation, known as suction lift. They may require additional priming or other mechanisms to overcome this limitation.

Limited pressure capability: Centrifugal pumps have a limited pressure capability, which may make them unsuitable for high-pressure applications. Multi-stage pumps can be used to increase the pressure capability, but this also increases the cost and complexity of the system.

Requires constant flow: Centrifugal pumps require a constant flow of fluid in order to operate effectively. Variations in flow can cause cavitation, which can damage the pump and reduce its effectiveness.

Energy efficiency: Centrifugal pumps can be less energy-efficient than other types of pumps, particularly at lower flow rates. They may require additional energy-saving measures, such as variable frequency drives, to reduce energy consumption.

Overall, while centrifugal pumps are widely used due to their simplicity, reliability, and ease of maintenance, they may not be suitable for all applications. The limitations of centrifugal pumps should be carefully considered when selecting a pump for a specific application.

Application of Centrifugal Pumps

Centrifugal pumps are widely used in many different industries and applications due to their simple design, ease of maintenance, and ability to handle a variety of fluids. Some common applications of centrifugal pumps include:

Water supply: Centrifugal pumps are commonly used in water supply systems, such as municipal water treatment plants, irrigation systems, and residential and commercial water systems.

HVAC systems: Centrifugal pumps are used in heating, ventilation, and air conditioning (HVAC) systems to circulate hot or cold water throughout a building.

Chemical processing: Centrifugal pumps are used in chemical processing industries to transport various chemicals and fluids, such as acids, bases, and solvents.

Food and beverage processing: Centrifugal pumps are used in food and beverage processing industries to transfer liquids such as milk, juice, and beer.

Pharmaceutical manufacturing: Centrifugal pumps are used in pharmaceutical manufacturing to transport various liquids and slurries during the manufacturing process.

Oil and gas production: Centrifugal pumps are used in the oil and gas industry to transport various fluids, including crude oil, natural gas, and drilling fluids.

Wastewater treatment: Centrifugal pumps are commonly used in wastewater treatment plants to transport wastewater and sludge.

Overall, centrifugal pumps are used in a wide range of industries and applications due to their versatility, efficiency, and reliability.

Advantage and Disadvantage of centrifugal pump

Advantages of Centrifugal Pump

High flow rates: Centrifugal pumps can handle large volumes of fluid and generate high flow rates, making them ideal for many applications that require rapid movement of fluids.

Low maintenance: Centrifugal pumps have a simple design and fewer moving parts than other types of pumps, which means they require less maintenance and are less prone to mechanical failure.

Easy to install: Centrifugal pumps are easy to install and can be quickly integrated into existing systems.

Wide range of applications: Centrifugal pumps are used in a wide range of industries and applications, including water supply, chemical processing, and HVAC systems.

Can handle various fluids: Centrifugal pumps can handle a variety of fluids, including water, chemicals, and petroleum products.

Disadvantages of Centrifugal Pump

Limited suction lift: Centrifugal pumps have a limited ability to lift fluids from a lower elevation, known as suction lift. This means they may not be suitable for applications that require high suction lifts.

Limited pressure capability: Centrifugal pumps have a limited pressure capability, which may make them unsuitable for high-pressure applications.

Requires constant flow: Centrifugal pumps require a constant flow of fluid in order to operate effectively. Variations in flow can cause cavitation, which can damage the pump and reduce its effectiveness.

Low efficiency at low flow rates: Centrifugal pumps may not be as efficient at low flow rates, which can result in higher energy consumption.

May not be suitable for high viscosity fluids: Centrifugal pumps may not be suitable for handling high viscosity fluids, such as slurries or heavy oils, which may require specialized pumps.

Overall, while centrifugal pumps offer many advantages, they may not be suitable for all applications. It is important to carefully consider the advantages and disadvantages of centrifugal pumps when selecting a pump for a specific application.

FAQ

What are the 2 types of centrifugal pumps?

Radial pump.

Axial pump.

What are the types of impellers?

Open impeller.

Semi-open impeller.

Closed impeller.

Vortex impeller.

Cutter impeller.

What is the working principle of the centrifugal pump?

The basic operating principle of centrifugal pumps is: forced vortex flow. This means that when a body of liquid receives the action of an external torque, the pressure head of the rotating liquid increases. This pressure increase is directly proportional to the velocity of the liquid.

You may also like

- 60-Interview questions & answers on centrifugal pumps

- Centrifugal pump working principle

- What happens when hydraulic oil Overheat