Table of Contents

Axial Piston Pump

When pistons of pump are arranged axially parallel to the driving shaft of the pump. It is known as axial piston pump.

It works on the principle of reciprocating motion of pistons with the help of swash plate or wobble plate for increasing pressure of oil to be supplied to the hydraulic system . An axial piston pump is a positive displacement pump that has a number of pistons in a circular array within a cylinder block.

Type

Axial piston pumps are classified according to

Axis of pump

1. In – line axial piston pump

2. Bent axis piston pump

In – line axial piston pump

In-line axial piston pumps has the piston are arranged inside the piston block parallel to each other i.e. in-line hence they are called as in-line axial piston pump…

In-line axial piston pump are classified as

1. Swash plate axial piston pump

2. Wobble plate axial piston pump

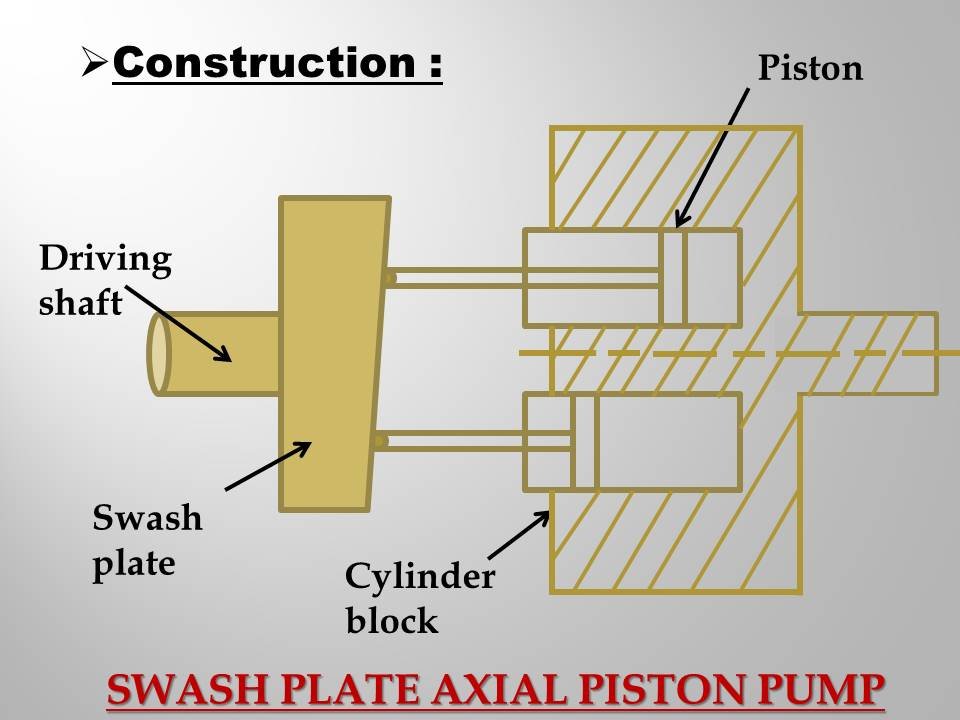

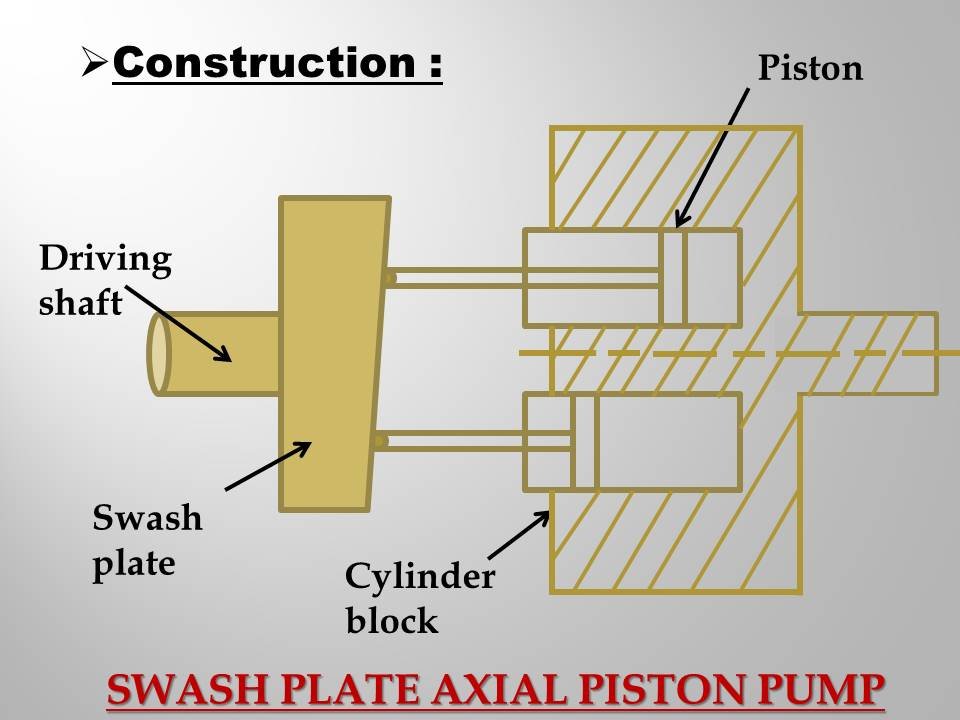

Swash plate axial piston pump

When swash plate or tilting plate is used to obtain to and fro motion of pistons for pumping of an oil, it is known as swash plate axial piston pump…

Principle

The angular surface of swash plate helps to produce reciprocating motion when rotates along with the piston rods of the pistons and increases pressure of oil.

Main parts of Axial piston pump

1. Drive shaft with cylinder block – It is rotating element of the pump in which cylinder block is mounted with shaft.

2. Piston – Pistons are mounted in the cylinder block with piston rods.

3. Swash plate – The swash plate being kept fixed and positioned at an angle with the axis of the cylinder block.

4. The shoe plate is attached to the angular surface of the swash plate.

5. Suction and discharge port – They are provided for suction and delivery of oil.

Working

- As the drive shaft rotates, it will cause rotary movement of the cylinder barrel. The piston shoes follows the surface of the swash plate.

- Since the swash plate has angular surface, the pistons reciprocates within the cylinder bore and thus oil is sucked during the one half of the circle of rotation and during other half of rotation, the oil is forced to the outlet port.

- In another design of swash plate axial piston pump, the location of stationary swash plate and the cylinder block are reversed and piston arrangement remains same.

- For fixed capacity axial piston pumps, the angle of swash plate is mostly 30degree. The flow rate of pump depends upon the number of cylinder(n), speed of pump(N), the bore diameter and stroke length of piston(e), and angle of swash plates.

- The volume calculated by

q = n . N . l . A

A = Area of piston bore

Function of swash plate

- Swash plate is an angular surface plate used in swash plate axial piston pump. It is provided to obtain to and fro motion of the pistons in the bore of cylinders.

- The stroke length of a piston is determined by the swash plate angle. With a large plate angle, the piston have a larger stroke where as smaller swash plate angle gives shorter stroke length.

- When the angle of swash plate becomes zero, no displacement of pistons takes place.

- The angle of swash plate can be changed to get variable piston displacement and volume flow rate .

- The maximum angle is generally limited 17.5degree from various design considerations.

- By varying the angle, pump output and flow can be changed from zero to maximums.

Advantages and Disadvantages of Axial piston pump

Axial piston pumps are a type of hydraulic pump commonly used in various industrial and mobile hydraulic systems. They offer several advantages and disadvantages:

Advantages:

High Efficiency: Axial piston pumps are known for their high mechanical and volumetric efficiency. This means they can convert a large portion of input power into hydraulic output power, resulting in less wasted energy and lower operating costs.

High Pressure Capability: These pumps can generate very high pressure, making them suitable for applications that require high-pressure hydraulic systems, such as in construction and manufacturing equipment.

Variable Displacement: Many axial piston pumps are designed with variable displacement mechanisms, allowing for precise control of fluid flow and pressure. This flexibility is valuable in applications where the load requirements vary.

Compact Design: Axial piston pumps tend to have a relatively compact and lightweight design compared to some other types of hydraulic pumps, making them suitable for mobile equipment where space is limited.

Low Noise Levels: Axial piston pumps often operate with lower noise levels compared to other hydraulic pumps, which can be important for applications in noise-sensitive environments.

Disadvantages:

Complex Design: The design of axial piston pumps is relatively complex, which can make them more expensive to manufacture, maintain, and repair. This complexity can also make them more prone to wear and damage.

Limited Contaminant Tolerance: Axial piston pumps can be sensitive to contamination in the hydraulic fluid. Even small particles or impurities in the fluid can lead to premature wear and reduced pump performance.

Lubrication Requirements: Proper lubrication is essential for the longevity of axial piston pumps. Inadequate lubrication can result in increased friction and wear.

Heat Generation: Axial piston pumps can generate heat during operation, which may require additional cooling measures in some applications.

Cost: Axial piston pumps are generally more expensive upfront compared to some other types of hydraulic pumps, which can be a significant consideration for budget-conscious projects.

Application of Axial piston pump

Some common applications of axial piston pumps:

Hydraulic Power Units (HPUs): Axial piston pumps are often used in hydraulic power units to provide hydraulic power for various machinery and equipment. These units are found in manufacturing, construction, and other industrial settings.

Construction Equipment: They are widely used in construction machinery such as excavators, bulldozers, and cranes to provide the hydraulic power needed for various functions, including lifting, digging, and steering.

Aircraft Hydraulic Systems: In aviation, axial piston pumps are employed in hydraulic systems that control landing gear, brakes, and other critical aircraft functions.

Marine Applications: They are used in ships and boats to power hydraulic systems for steering, anchor handling, and winch operations.

Industrial Machinery: Axial piston pumps can be found in a variety of industrial machinery, including injection molding machines, metal forming equipment, and hydraulic presses.

Automotive Manufacturing: Axial piston pumps play a role in automotive manufacturing processes, such as press machines for stamping, welding, and assembly.

Material Handling Equipment: Forklifts, conveyors, and other material handling equipment often use axial piston pumps to operate the hydraulic systems responsible for lifting and transporting goods.

Mobile Hydraulic Systems: Axial piston pumps are frequently used in mobile hydraulic systems, such as those found in mobile cranes, aerial platforms, and firefighting equipment.

Hydraulic Elevators: They are used in hydraulic elevator systems for lifting and lowering the elevator car.

FAQ

- What is the purpose of a swash plate in a piston type pump?

Swash plate causes pistons to reciprocate. In these pumps the size and number of pistons as well as their stroke length also determine the displacement. The stroke length is controlled by the swash plate angle. In variable-displacement models, the swash plate is installed in a movable yoke - How does axial piston pump work?

In an axial-piston pump, the pistons and cylinder rotate around the center, longitudinal axis. The pistons and shoes move in and out of the cylinder because they are sliding upon a stationary, variable angle, swashblock. As the pistons rotate, they alternate between being connected to an inlet port and an outlet port. - What is a swash plate in hydraulics?

In a hydraulic motor, a swash plate aids in transforming the axial reciprocating motion of the axial pistons into rotary motion. - What is the purpose of swash plate?

A swashplate is a device that translates input via the helicopter flight controls into motion of the main rotor blades. - In which pump swash plate is used?

Axial piston pumps - What happens when a swash plate is vertical?

Since there is no reciprocating motion when the swash plate is in vertical position, no displacement occurs.

You may also like