Table of Contents

Battery ignition system

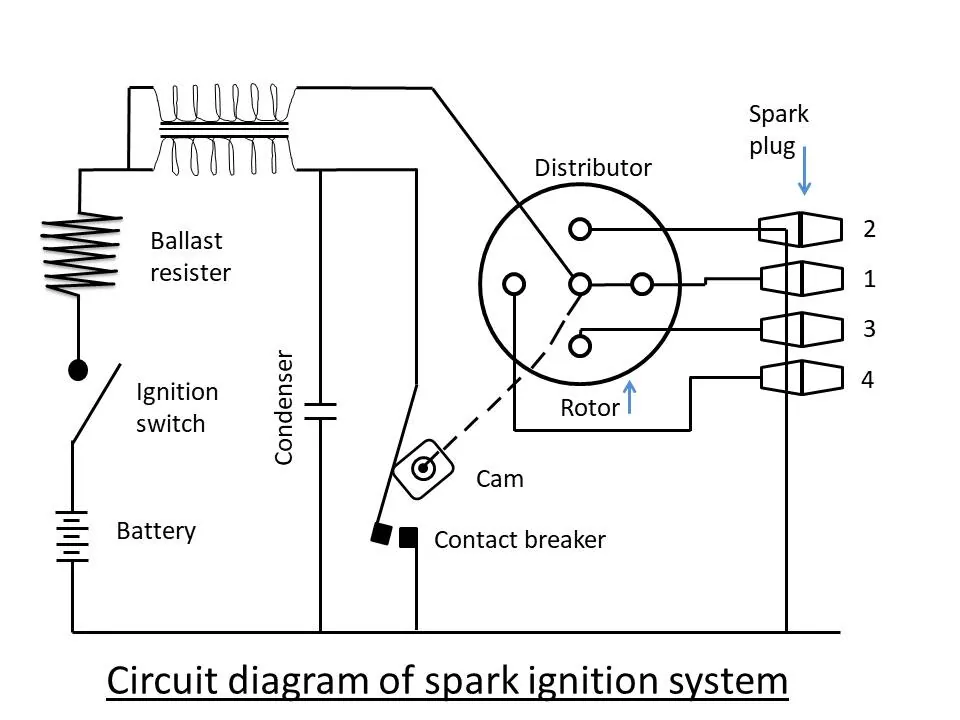

The battery ignition system consist of battery, ignition switch, ignition coil with a ballast registor, distributor housing, contact breaker points, cam, condenser, rotor and advance mechanism, spark plug low and high tension wiring.

It Consist of

The ignition coil consist of two coil, primary coil having 100 to 200 turn and secondary coil having 20,000 turn.

The primary winding is connected to the battery through an ignition switch and contact breaker point.

While secondary winding is connected to spark plug through distributor.

A ballast resistor is provided in series with the primary winding to regulate primary current and passes more current in primary circuit during starting.

A rotating cam at camshaft speed operates the contact breaker and causes the breaker point to open and closed.

When the ignition switch is on and the contact breaker point are closed, the current flow in primary winding and builds up a magnetic field.

As soon as the contact breaker point open, the current flow in primary winding is stopped and a magnetic field collapse, cuts across the secondary winding and induces a voltage which is accomplished by a current.

This magnetic field also cuts the primary winding and induced voltage in this as well as in the secondary winding.

The voltage in primary winding always opposed the action producing it thus effect is to slow down the build up of the current in the primary winding when breaker point closes.

Due to this continuous process a slow building up of the magnetic field consequently lower voltage in secondary circuit, result slow collapse of magnetic field which causes sparking at breaker point. This arcing increase wear and reduce the life of contact point.

It is necessary to prevent arcing and this can be achieve by using a condenser in primary winding across the contact breaker, when the contact point open, the current flow in primary winding is stored and it become charged.

It discharges immediately back into primary circuit in reverse direction, thus cause to quick collapse of magnetic field and a high voltage is build up in secondary circuit which supplies to the spark plug through distributor.

If this voltage is higher than breakdown voltage a spark occur across the spark plug gas causing the ignition of charge in combustion chamber.

Magneto Ignition system

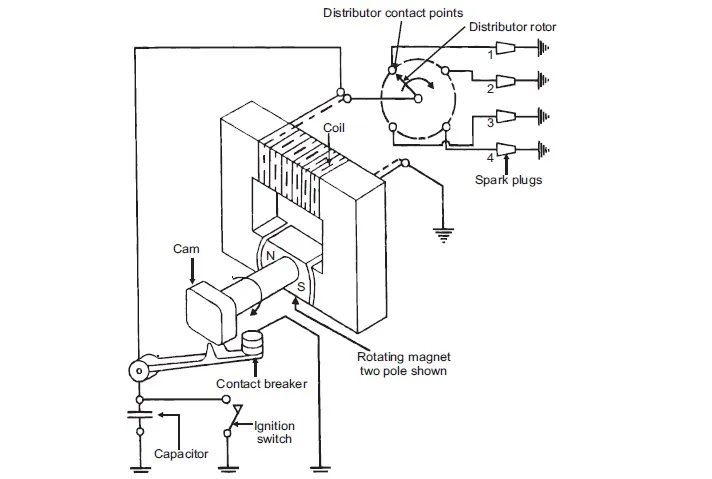

Magneto is a special type of electric generator. It consist of a magneto instead of a battery, which produce and supplies current in primary winding.

The magneto consist of a fixed armature having primary and secondary windings and a rotating magnet assembly. When the magnet, rotate in fixed armature, current flow in primary winding and high voltage is produce in the secondary winding.

This high voltage is send to the spark plug through distributor.

Contact breaker point is open or closed by rotating cam at cam shaft speed. During starting cranking speed is low current generated by magneto is very low.

As engine speed increase, current increase, hence for starting purpose a separate battery is required. The magneto may be rotating armature type or rotating magnet type.

The Magneto is based suitable for high speed, therefore used for sport and racing cars, craft engine.

Electronic Ignition System

The need to avoid frequent breaker contact servicing and to provide longer ignition system life and better consistency of firing, thereby, avoiding the power loss and increase fuel consumption and hydrocarbon emissions from the engine, has led to the development of new ignition system concepts using solid state devices which aim at partial or total solution to problems in encountered with the conventional ignition system.

Principle

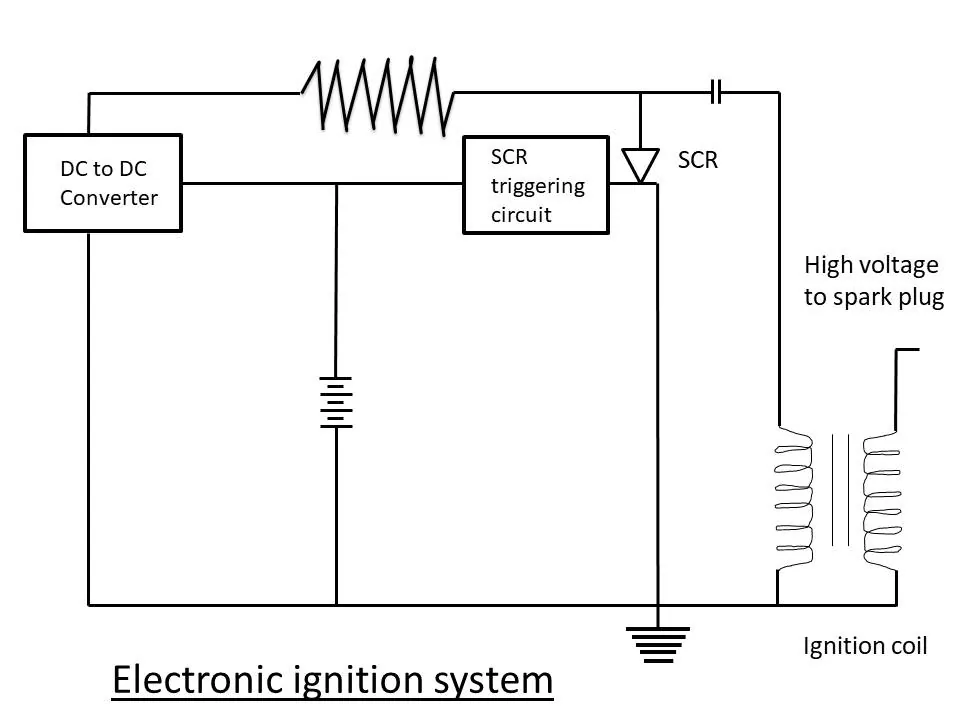

In this system a timer is used in the distributor instead of contact breaker.

This timer may be a pulse generator or hall effect switch which triggers the ignition module called electronic ignition control unit.

This control unit primary contain transistor circuit whose base current is trigged off and on by a timer which result in the starting and stopping of the primary current.

Electronic ignition system

In this system, the input coil is similar to the primary winding in the armature. As the flywheel magnet passes past the input coil, an alternating current charges the capacitor.

The capacitor absorb and stores electrical energy for short time.

The diode in the circuit allow the current to flow only in one direction. This current flow to the capacitor and charges the silicon controller rectifier is still turned off.

The silicon controller rectifier (SCR) is an electronic switch and has no moving part. This switch normally acts to open switch to electric current.

This switch can be turned on by a small voltage applied to the gate connection. The trigger coil provide the gate voltage to turn the SCR.

The magnet after passing the input coil charges the capacitor, passes past a small trigger coil. Then trigger coil produce enough voltage to trigger the SCR.

The ballast registor prevent the excessive current which may damage the SCR. The trigger voltage turn the SCR and it open a path for the capacitor which was them holding a charge.

The capacitor thus discharges the electrical energy stored in the primary of the pulse transformer. The pulse transformer is similar with ignition coil. It has primary winding. When the current passes through primary winding, a strong magnetic flux build up.

The pulse transformer has secondary winding having several turn of wire. This magnetic field develop very high voltage this high voltage is send to spark plug to cause the spark in combustion chamber.

The spark timing is determined by the position of trigger coil.

There are two trigger coil to trigger the SCR. The first is connected to the SCR through high value registor to allow ON SCR only at high speed and other to allow ON at low speed.

Advantage and Disadvantages of Electronic Ignition System

- The advantages of solid state are numerous but big one is no moving parts. This should translate the control and reliability impossible to achieve any mechanical system.

- The term engine tune up is nearly meaningless with respect to modem ignition system. Cut side of replacing plugs and inspecting wiring there is not much else to do.

- Better starting with cold engine.

- Less possibility of arcing at spark plug.

- Longer life due to stable timing.

- Produce a maximum output voltage which is attainted in a very short time and with a very limited discharge, resulting and regular engine running, even with dirty spark plug and wide, plug gap.

- No change in ignition timing due to absence of C.B. point, cam, etc. which expose to wear and tear.

Capacitive discharge Ignition System

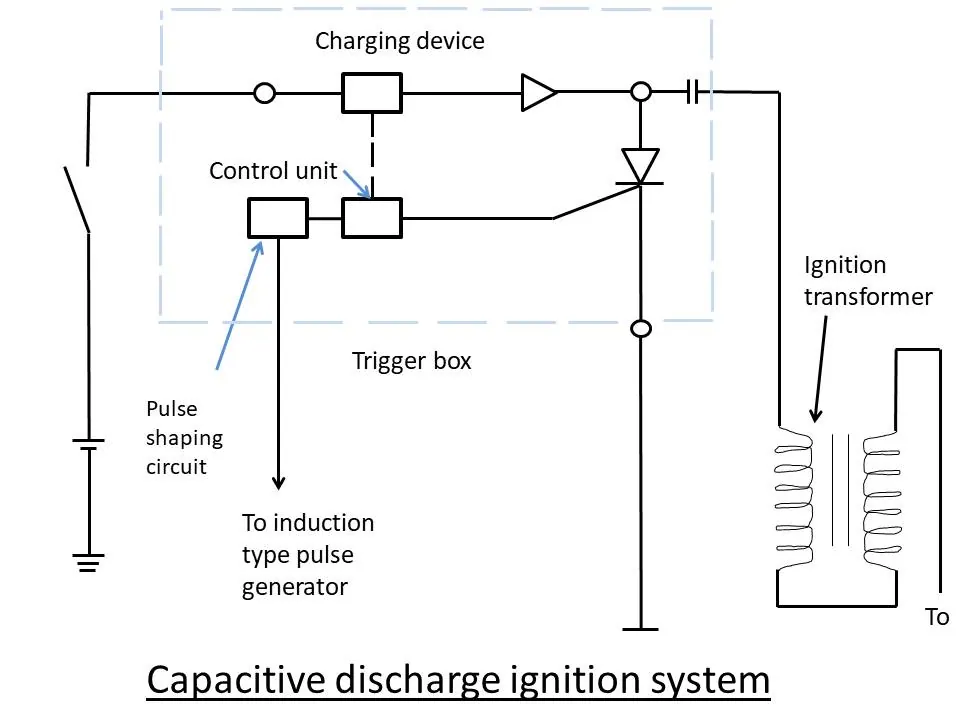

The systematic circuit diagram of the capacitive discharge ignition system shown in figure. In this system a capacitor rather than and induction coil, is used to stored the ignition energy.

The capacitance and charging voltage of the capacitor determine the amount of storage energy.

The ignition transformer step up the primary voltage generated at the time of spark by the discharge of the capacitor through the thyristor, to the high voltage required at the spark plug.

The CDI trigger box contain the capacitor thyristor power switch, charging device ( to convert battery voltage to the charging voltage of 300 to 500 volt by means of pulse via. a voltage transformer ) pulse shaping unit and control unit.

The advantage of using this system is that it is insensitive to electrical shunt resulting from spark plug fouling.

Because of the fast capacitive discharge, the spark is strong but short which leads to ignition failure during lean mixture operating condition. This is the main disadvantages of the CDI system.

CDI ignition system is most widely used today on automotive and marine engine. A CDI module has capacitor storage of its own and send a short high voltage pulse through the coil. ( about 200 + voltage)

The coil now acts more like a transformer instead of a storage inductor and multiply this voltage ever higher. Modern CDI coil step up the voltage about 100:1 so a typical 250 volt CDI module output is stepped upto over 25000 volt output from the coil. The CDI output voltage of course can be higher.

The huge advantage of CDI is the higher voltage coil output and hotter spark. The Spark duration is much shorter ( about 10 to 20 microsecond ) and accurate.

This is better at high RPM but can be a problem for both starting and lean mixture/high compression situation. CDI system can and do use low resistance coil.

Advantages of CDI ignition system

- CDI is the higher voltage coil output and hotter spark and accurate.

- This is better at high RPM.

- Less possibility of arcing at spark plug.

- Longer life due to stable timing.

- Spark plug life is more due to less electrode wear.

- No change in ignition timing due to absence of C.B., cam, which exposed to wear and tear.

FAQ’s

What are the 3 types of ignition systems?

Battery ignition system

Magneto ignition system

Electronic ignitionsystem

What is ignition system and its function?

Ignition system, in a gasoline engine, means used to produce an electric spark to ignite the air-fuel mixture; the burning of this mixture in the cylinders produces the motive power.

What are the 4 types of ignition systems?

Battery ignition system

Magneto ignition system

Electronic ignitionsystem

Capacitive discharge ignition system

What is the principle of ignition system?

When the electrical current is initially turned on, the current flow increases rapidly to its maximum value. Simultaneously, the magnetic field or flux will progressively grow to its maximum strength and will stabilize when the electric current is stable.

What are four ignition functions?

Ignition involves four basic and sequential functions: the provision of low voltage electricity, the amplification of the voltage to a high level, the distribution of a pulse of high voltage electrical current to each of the combustion chambers, and finally the ignition. discharge in the form of sparks.

What are the components of ignition?

The basic components of the ignition system are a storage battery, an induction coil, a device for producing synchronized high-voltage discharges from the induction coil, a distributor, and a set of spark plugs.

What is the voltage of ignition?

The ignition system normally generates 10-30 kV secondary voltages.

You may also like