Table of Contents

Definition

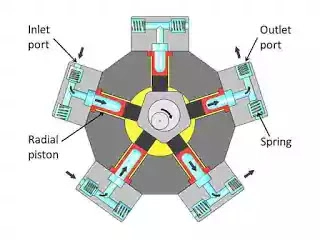

When pistons are arranged along a radius of the cylinder block similar to vane pump, it is called as Radial piston pump.

Construction

It consists of –

a) Cylinder blog : The pistons are arranged radially in a slot of cylinder block. They move perpendicular to the shaft centre line.

b) Radial pistons : The radial pistons are mounted in the slots or bores of cylinder block usually 4 to 6. They are provided with the spring to maintain contact with the cam ring.

c) Cam ring : It is the outer ring which is positioned eccentrically with the cylinder block axis. It help to obtain to and fro movement of pistons. The eccentricity can be varied by using adjusting screw.

d) Inlet and Outlet ports : The inlet and outlet ports are provided at the centre of the block and separated with the help of pintle.

What is Radial Piston Pump | Definition, Construction, Working, Advantages And More

Working

When driving shaft is rotate, it will cause rotation of the cylinder block(rotor). During rotation of block, the pistons are thrown out by centrifugal force and pushed back due to eccentricity between cam ring and cylinder block.

Now movement of rotor is observed by step it shows, that during movement of rotor from piston 1 to the piston 2, the radius of rotation increases and piston is forced out towards cam ring. The piston is pulled out and causes suction of oil.

During next part of rotation, the piston moves from point 2 to point 3. The radius of piston movement is almost same and oil is carried out by the slots of the rotor.

When rotor moves from 3 to 4, the radius of rotation gradually decrease and piston moves towards the centre of the pump. As piston get pushes towards centre, it will cause pumping of oil to the discharge port.

From point 4 to 1, as pintle wall is in contact with the piston no suction and delivery occurs.

These pumps are quite robust and work at a high rpm with very high flow rate about 2000 li/min.

What is Radial Piston Pump | Definition, Construction, Working, Advantages And More

Advantages

1) High pressure range : Up to 450-500 bar. Maximum pressure is about 1000 bar.

2) High volumetric efficiency

3) Variable delivery

4) Viscosity range high

5) Noiselsess operation

Disadvantages

- Cost is high

- Cleaning difficult

Application

Radial piston pumps are used in plastic- and powder injection molding and wind energy.

Radial piston pumps are the only pumps capable of working satisfactorily at such high pressures, even under continuous operation.

It’s used for machine tools, such as the displacement of cutting emulsion, and as a supply for hydraulic equipment like cylinders.

They are also used in high-pressure units (HPU) for overload protection, and for test rigs.

FAQ

What is Radial piston pump?

When pistons are arranged along a radius of the cylinder block similar to vane pump, it is called as radial piston pump.

What is pressure range of radial piston pump?

High pressure range : Up to 450-500 bar. Maximum pressure is about 1000 bar.

What is the difference between axial piston pump and radial piston pump?

A radial pump has the pistons arranged radially in a cylinder block, while the pistons in the axial units are parallel to each other and to the axis of the cylinder block.

What is the advantages of Radial piston pump?

It’s volumetric efficiency is high also viscosity range high.

You may also like