Table of Contents

Principle

When a pair of meshing screws are used to increased pressure of oil, It is know as screw pump.

A screw pump is a type of positive displacement pump that utilizes the rotation of a screw-like rotor to move fluid from one place to another. It is also known as an Archimedes’ screw pump, named after the ancient Greek mathematician Archimedes who first described its principles.

The screw pump consists of a helical rotor, which is typically a metal or plastic screw-shaped element, and a surrounding casing or stator. The rotor is usually driven by an electric motor or other power source, causing it to rotate within the stator. As the rotor turns, the fluid enters the pump through the inlet and moves along the helical thread of the rotor.

The rotation of the screw creates a series of sealed cavities or chambers within the pump. As the fluid progresses along the length of the screw, the expanding volume of each chamber draws in the fluid, and the shrinking volume of the chamber pushes the fluid towards the pump outlet. This action effectively displaces the fluid from the suction side to the discharge side of the pump.

Screw pumps are commonly used in a variety of applications, including wastewater treatment plants, industrial processes, oil refineries, marine vessels, and other situations where the efficient movement of viscous or abrasive fluids is required. They are particularly well-suited for handling liquids with high solid content, sludge, or thick substances that may be difficult to pump using other types of pumps.

Overall, screw pumps offer reliable and efficient pumping solutions for a wide range of applications, particularly for viscous fluids or challenging pumping conditions.

Construction

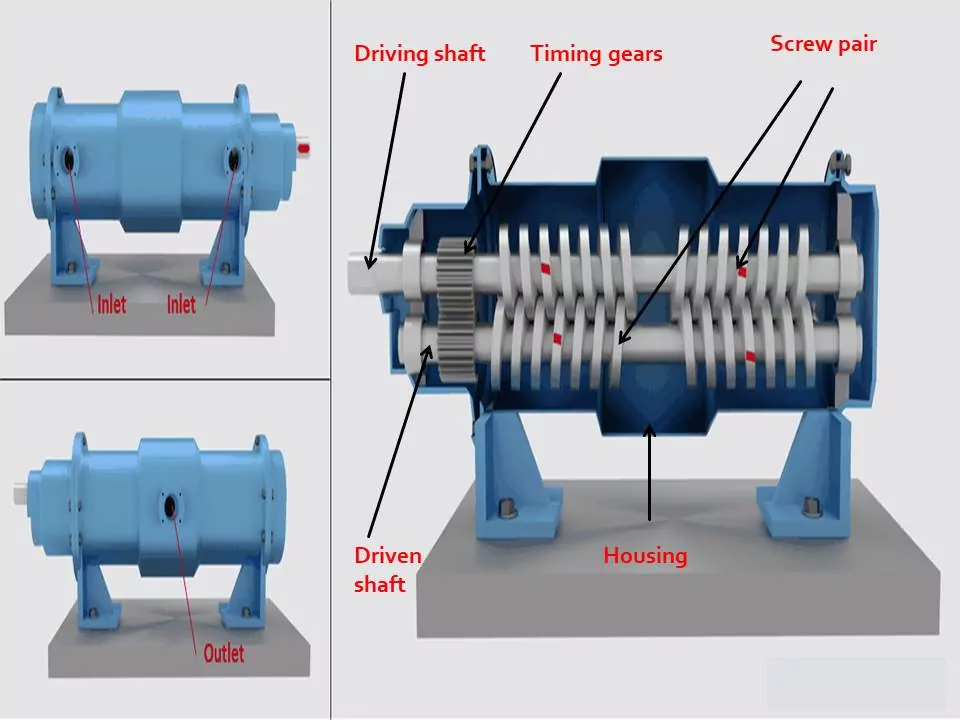

The screw pumps are available in design with one, two screws and three screws. This is two screw gear pump. It’s positive displacement pump.

It consists of following main parts

Screw pair – The meshing pair of screws is mounted with the help of spindle mounted in bearing. One of screw is connected to the driving shaft.

Timing gears – Timing gears are provided to maintain a running clearance between two meshing screws. With both the driver and driven screw running with a very fine clearance; there is always a chance of contact. One such contact can wear the edge of the screw reducing the output pressure drastically.

Suction and discharge port – A screw pump has different suction and discharge ports as the fluid moves axially along the screw toward the discharge port. Inlet suction port is provided for suction of oil and discharge port is provided to deliver high pressure of oil..

Housing – It is body of the pump which accommodates screw pair, timing gears and suction and discharge port.

Rotary and Stationary Seal – Screw pumps are fitted with a pair of mechanical seal with one on both side to act as a sealing surface between the pump dry side and the working liquid. This keeps the bearings and the timing gear separate on one side of the pump.

Working

When pump is started by prime mover, the driving screw rotates and drives the other screw and creates suction of oil.

The oil entered through inlet suction ports is carried out linearly due to helical recesses between screw pair. The oil does not rotate but moves linearly .

Similar to gear pump, the meshing of the thread flanks forces oil to flow in the space between the rotor and housing wall.

The volume of the oil moves forward uniformly with the rotation of screw along the axis and oil pressure is gradually increased.

The oil from both the ends comes towards the centre of the pump where discharge port is located.

Now the oil is discharged through discharge port to the hydraulic system. The flow rate of the oil can be varied by varying the drive motor speed .

Performance of Srew Pump

Screw pump can rech upto 180 to 56,781 liter per minute when it’s total head ranges 3 to 310 bar. Various sizes with pumping speed ~ 60 – 1200 m³/h are available.

Advantages and Disadvantages of Srew Pump

Advantages

Reliable performance.

Operate at very high speeds upto 3500rpm and sometime even higher speed

Continuous discharge

Silent operation

Better hydraulic control

Ability to handle high-viscosity fluids: Screw pumps are capable of effectively pumping fluids with high viscosity, such as heavy oils, sludge, and molasses.

Self-priming: Screw pumps are typically self-priming, meaning they can create suction and draw fluid into the pump without the need for additional priming devices.

Gentle pumping action: Screw pumps provide a smooth and steady flow without causing excessive shear or agitation to the pumped fluid, making them suitable for delicate or shear-sensitive substances.

Minimal pulsation: Screw pumps generate minimal pulsation or pressure fluctuations, resulting in a more stable flow and reduced stress on the piping system.

Disadvantages

Screw manufacturing difficult

Unsuitable for high viscosity oil

Low efficiency

They may not be as efficient as other pump types for low-viscosity fluids, and they can be prone to wear and damage when handling abrasive substances. Additionally, the design and construction of screw pumps can be more complex and expensive compared to some other pump types.

Application

It is used for fuel transfer, high pressure fuel injection, lubrication and hydraulic power implication.

It is suitable for industrial application like marine industry, refineries, chemical plant, heavy industries with hydraulic power control and power plant etc.

FAQ

What are the types of screw pumps?

Screw Pumps Types

One-Screw Pump

Two Screw Pump

Three Screw Pump

Four Screw Pump

Five-Screw Pump

What is difference between gear pump and screw pump?

Gear pumps work by intermeshing gears with external or internal type. As gear pumps are virutally “single stage positive displacement” pumps with less pressure capability than screw pumps. Screw pumps have a longer screw where the pressure is divided along the length of the screw.

You may also like

What is Balance Vane Pump – Principle, Construction, Working