Table of Contents

Definition

When a pressure control valve is placed in a such manner that it will actuate the operation in a sequence one after another, it is called as sequence valve .

Principle

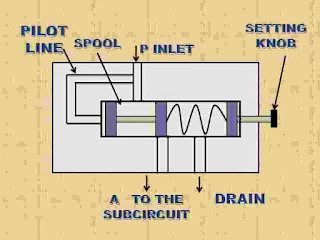

It is spool operated valve in which internal pilot line is used to build up pressure to actuate the sub circuit in a sequence.

Construction And Working

The sequence valve consists of spring loaded spool, setting screw knob, valve body with inlet port, port for sub circuit and drain port.

The internal pilot line is provided to operate the spool. Drain is provided for any internal leakage of oil.

This valve is mainly placed in the oil path of two actuators where sequence is desired. When the first actuator completes it operation, the oil will flow towards the inlet of the sequence valve.

It will enter in the pilot line and exerts a pressure from bottom side of the spool. The spool moves upward when sufficient pressure is build up and connects inlet port to the subcircuit port to supply oil to the another actuator.

Example of sequence operation

In this exmple, there are two operations first one is clamping of job with hydraulic cylinder and second one is drilling in work piece. It is used to actuate sequence of clamping and drilling.

In this first clamping is done by hydraulic cylinder and it hold workpiece firmly, then buildup pressure will open the sequence valve and rotates the hydraulic rotor for drilling.

Advantages and Disadvantages of Sequence Valve

It is a type of pressure control valve used in hydraulic systems. It is designed to control the sequence in which hydraulic actuators or functions operate. Here are some advantages and disadvantages of using a sequence valve:

Advantages

Control of Actuator Sequence: The primary advantage of a sequence valve is its ability to control the order in which hydraulic actuators or functions operate. This is particularly useful when you need a specific sequence of events to occur, such as ensuring that one actuator completes its task before another actuator starts. It allows for precise control over the operation of multiple actuators in a hydraulic system.

Safety: Sequence valves can enhance safety by ensuring that certain actions are completed before others. For example, in a hydraulic system controlling heavy machinery, a sequence valve can prevent potentially hazardous situations by ensuring that certain movements or operations occur in the correct order.

Simplicity: Sequence valves are relatively simple devices, consisting of a check valve and an adjustable pressure setting. Their straightforward design makes them easy to install and maintain.

Disadvantages

Limited Flexibility: One of the main disadvantages of sequence valves is their limited flexibility. They are typically set to operate at a fixed pressure threshold. If the pressure required for a particular actuator or function changes, the sequence valves may need to be adjusted or replaced. This lack of adjustability can be a drawback when dealing with varying operating conditions or system requirements.

Lack of Feedback: Sequence valves do not provide feedback on their operation. Once the set pressure is reached, they open and allow flow to the downstream actuator. However, they do not provide any indication of the actual pressure or force being applied. This can make it difficult to monitor or troubleshoot the system.

Complexity in Large Systems: While sequence valves are simple devices on their own, they can add complexity to larger hydraulic systems. As the number of sequence valves increases, the system becomes more intricate, requiring careful planning and design. Additionally, the interplay between multiple sequence valves can sometimes lead to unintended interactions or conflicts.

Application

Sequence valves can be used for movement of material from one location to another location.

It is used for machining and clamping of workpiece.

Sequence valves are commonly used in pressure dependent sequencingcircuits.

FAQ

Which valve is used to perform two operations in sequence?

Sequence valve

What is the function sequence valve give its example?

Sequence valves control the sequence of operation between two branches in a circuit; that is, they enable one unit to automatically set another unit into motion. An example of the use of a sequence valve is used for machining and clamping of workpiece.

What is the difference between a sequence and counterbalance valve?

Sequence valves always have an external drain connected directly to tank. Counterbalance valves are internally drained, except when used in some regeneration circuits.

Why do we use sequence valves?

Sequence valves can be used to sense pressure (port 1) in one circuit and then open and supply oil to a secondary circuit (port 2) at a predetermined pressure.

What is sequential valve?

It is a pressure valve designed to open when its set pressure is reached, providing a path of flow alternate and sequential to the primary circuit.

You may also like