Table of Contents

Definition

Spring Loaded Accumulator used spring force to store hydraulic energy.

A spring-loaded accumulator is a type of energy storage device used in hydraulic systems. It consists of a cylindrical chamber with a movable piston or diaphragm and a preloaded coil spring. The accumulator is connected to the hydraulic system and is designed to store fluid under pressure.

Spring-Loaded Accumulators are hydraulic accumulators that utilize a spring to store and release energy in the form of pressurized hydraulic fluid. These accumulators find application in various industrial and hydraulic systems where the need for energy storage, shock absorption, or maintaining consistent pressure is essential.

Construction

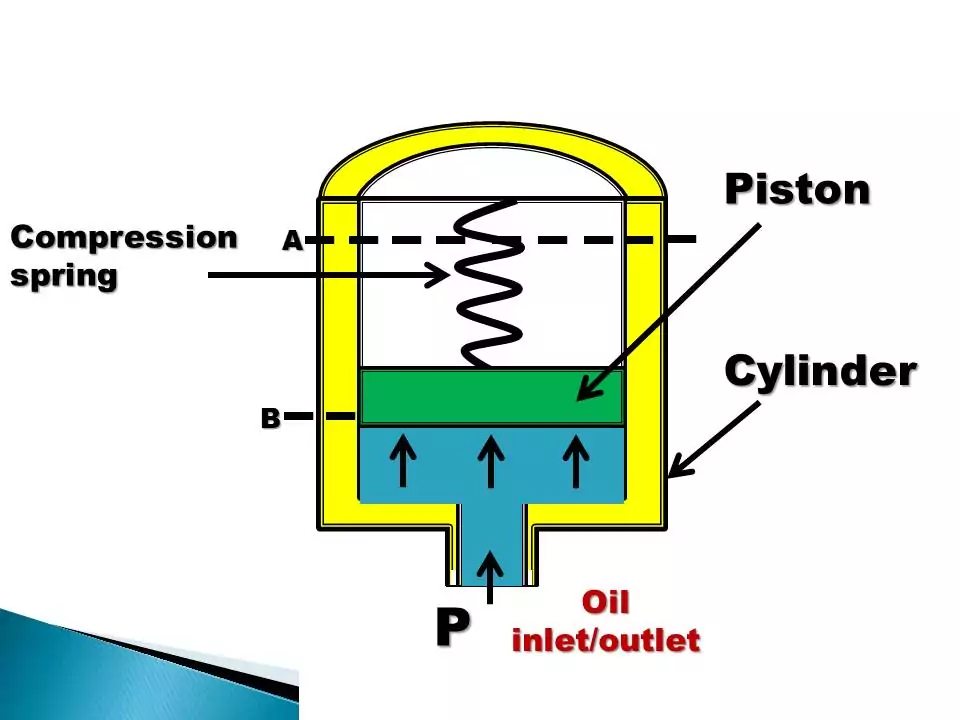

A spring loaded accumulator consists of cylinder body, a movable piston and a spring.

The spring applies a force to the piston. As dead weight accumulator is requires more bulky weights, spring provided large force in a limited area for the same pressure.

The spring used in this accumulator is compression spring which exerts force on the piston.

Working

When pressurized oil enter from the inlet at the bottom, it pushes the piston in the upward direction against the spring force.

Piston moves from the lower end to the upper end spring get compressed. When piston reaches the upper stop end, the accumulator is fully charged.

Accumulator is connected to the application point, spring pressure forces the oil under pressure through the outlet port. When spring is fully expanded the accumulator is unloaded and discharged.

Symbol

Advantages of Spring Loaded Accumulator

They are compact and smaller.

Mounting is easy.

Energy storage: Spring loaded accumulators allow for the storage of energy in the form of compressed gas or fluid. This stored energy can be released rapidly when needed, providing additional power during peak demands or when the hydraulic pump is unable to keep up with the system requirements.

Smooth operation: By storing energy during periods of low demand and releasing it during peak demand, spring loaded accumulators help to smooth out pressure and flow fluctuations in the hydraulic system. This can enhance the overall performance and efficiency of the system.

Emergency power source: In the event of a power failure or shutdown of the hydraulic pump, spring loaded accumulators can serve as an emergency power source. They can provide a temporary supply of pressurized fluid, allowing critical operations to continue until power is restored or an alternative power source is activated.

Reduces pump size and power requirements: Spring loaded accumulators can reduce the size and power requirements of the hydraulic pump. By storing and releasing energy as needed, the pump can operate at a lower average power level, resulting in energy savings and potentially smaller pump size.

Disadvantages of Spring Loaded Accumulator

Less capacity

Operate at low pressure

The pressure is not uniform and does not remain constant.

Limited energy storage capacity: Spring loaded accumulators have a limited capacity for storing energy. The amount of energy available depends on the size of the accumulator and the compression of the spring. This limitation may restrict their use in applications that require sustained high-power output or extended energy storage.

Pressure fluctuations: As the spring compresses and decompresses, there can be pressure fluctuations in the hydraulic system. This can affect the performance and stability of the system, especially if the pressure fluctuations are significant or frequent.

Maintenance requirements: Spring loaded accumulators require regular inspection and maintenance to ensure proper functioning. The springs may need periodic checks and replacement to maintain their effectiveness. Additionally, the pressure vessel and seals must be monitored and maintained to prevent leaks or failures.

Safety considerations: Spring loaded accumulators operate under high pressure, and failure or over-pressurization can lead to hazardous situations. Proper design, installation, and maintenance are crucial to ensure the safety of personnel and equipment. Regular inspections and compliance with safety standards are essential.

Application of Spring Loaded Accumulator

Hydraulic Systems: Spring-loaded accumulators are used in hydraulic systems to maintain stable pressure levels. They help reduce pressure fluctuations, which can be crucial for the efficient and safe operation of machinery and equipment.

Hydraulic Braking Systems: In heavy machinery and vehicles, spring-loaded accumulators are used in hydraulic brake systems. They help store energy and ensure a consistent and reliable supply of hydraulic fluid for braking, especially in emergency braking situations.

Construction Equipment: Hydraulic systems in construction machinery, such as cranes, excavators, and loaders, often employ spring-loaded accumulators. These accumulators assist in lifting and lowering heavy loads and provide smooth, controlled movement.

Railway Systems: Spring-loaded accumulators are used in hydraulic suspension systems for trains. They help absorb shocks and vibrations, providing a smoother and more comfortable ride for passengers.

Aerospace Applications: Some aircraft hydraulic systems utilize spring-loaded accumulators to maintain pressure in various components like landing gear and brakes. These accumulators ensure consistent and reliable operation, even during high-stress conditions.

Hydraulic Presses: Spring-loaded accumulators are employed in hydraulic press applications. They store energy and provide rapid force or pressure when needed for tasks like metal forming, molding, or stamping.

Machine Tools: In precision machining and metalworking equipment, spring-loaded accumulators help to reduce shock and vibration, providing smoother and more accurate operations.

Pneumatic Systems: While spring-loaded accumulators are primarily used in hydraulic systems, they can also be found in some pneumatic systems. These accumulators help store and supply compressed air for various applications.

Marine Industry: Spring-loaded accumulators are used in marine hydraulic systems for tasks like stabilizing ships, controlling rudders, and operating winches and cranes.

Material Handling Equipment: Forklifts, conveyor systems, and other material handling equipment use spring-loaded accumulators to provide hydraulic power for lifting, tilting, and other functions.

FAQ

What is the function of the spring accumulator?

In a spring-loaded accumulator, springs create pressure on the piston to pump fluid. The rate at which the fluid is pumped depends on the compression rate of the spring and this type of accumulator is typically best suited for mobile applications and those with smaller fluid volumes.

What is spring loaded accumulator?

Spring-loaded accumulator: This accumulator is used in some hydraulic systems of engineering equipment. It uses the energy stored in the springs to create a constant force on the liquid contained in an adjacent ram assembly.

What is the application of the accumulator?

Accumulators are extremely effective in reducing hydraulic system noise caused by piston pumps, relief valves and the complexities of some hydraulic circuits.

You may also like