Table of Contents

Tyre

- A tyre is a cushion provided with an automobile wheel

- Tyre must be large and strong to support the load they are expected to carry

- They absorb shocks from road irregularities they must develop tractive force on accelerating, cornering and breaking.

The tyre is a ring-shaped component that surrounds the edge of a wheel to transfer a vehicle’s load from the axle through the wheel to the ground and provide traction on the surface the wheel is traveling on.

Specification of tyres

The tyres are specified and designated by the nominal size of their sectional width and rim diameter. They are marked as

P185/75 R 14

P – Tyre type ( P – Passanger, T- Temparary, C – Commercial )

185 – Section width

75 – Aspection ratio = Section height / Section width

R – Constructional type ( R- Radial, B – Bias-belted, D – Diagonal )

14 – Rim diameter in inches

Tyre life and performance are determined by factor like tyre load. Inflation, pressure driving habit and vehicle maintenance.

Requirement of good tyres

- It must be strong to carry load and resist damage.

- It must be flexible to cushion all shocks and impacts atleast partly.

- It must have a long life.

- It must provide comfortable right to passengers.

- It must meet its requirement in all weather and on all surfaces without over heating.

- It must respond accurately to steering without deflection by the ridge on the road.

- It must provide road grip for traction, cornering, accelerating and breaking.

Material used for tyre

Tires are typically made from a combination of various materials, each serving a specific purpose to ensure the tire’s performance, durability, and safety.

The primary materials used in tire manufacturing include:

Rubber:

Natural Rubber: Derived from the latex sap of rubber trees, natural rubber provides elasticity and resilience to the tire.

Synthetic Rubber: Chemically produced rubber compounds, such as styrene-butadiene rubber (SBR) and polybutadiene rubber (BR), are often used in conjunction with natural rubber to enhance specific tire characteristics.

Fabric Reinforcement:

Layers of fabric, usually made from materials like polyester, rayon, or nylon, are embedded in the tire to provide strength and stability. These layers are often referred to as plies.

Steel:

Steel belts or plies are incorporated into the tire to improve its strength, stability, and resistance to punctures. It also help maintain the shape of the tire, especially at high speeds.

Carbon Black:

Carbon black is a fine, powdery substance made from incomplete combustion of hydrocarbons. It is added to the rubber compound to enhance the tire’s strength, durability, and resistance to ultraviolet light.

Chemical Additives:

Various chemicals, such as sulfur and accelerators, are added to the rubber compound during the vulcanization process. Vulcanization is a chemical process that enhances the rubber’s properties, making it more durable and resistant to heat.

Silica:

Silica is sometimes used as a reinforcing agent in tire tread compounds. It improves traction and reduces rolling resistance, contributing to better fuel efficiency.

Fillers:

Other fillers, such as clay or calcium carbonate, may be added to the rubber compound to achieve specific performance characteristics and reduce costs.

Type of tyres

- Tubeless tyre

- Conventional tube tyre

- Carcass type tyre

a) Cross ply tyre

b) Radial ply tyre

c) Belted bias tyre

Tube tyre

It is a traditional tyre. It encloses a tube in which air is forced to a high pressure as a cushioning medium.

The outer portion of the tyre which rolls on the road is made of synthetic rubber and is called tread. At the inner edges, beads are formed by reinforcing with steel wires.

The beads act as strong shoulders, forbearing against the wheel rim. Rayon cords are formed into a number of piles.

Where the beads and cords give strength to the tyre,the treads provide resistance against slipping and thicker surface at the outer periphery.

Tubeless tyre

Tubeless tyre does not enclose a tube.

The air under pressure is filled in the tyre itself through a not return valve is fitted to the rim.

It consist of outer cover with a special inner lining. It does not employ any sealant and depends upon air- tight card fabric to retain the air.

The tubeless tyre is lighter and runs cooler than the tube tyre.

Advantages of tubeless tyres over

- The tubeless tyre are easier to fit.

- When punctured it deflects slowly in contrast to tube tyre where air leaks out fast. This is because of soft lining has self-sealing effect.

- A temperature puncture repair can be made without removing the wheel by stopping the whole with a special rubber plug.

However tubeless tyre cannot be used in spoked wheels since in that case the rim is perforated.

The tubeless tyre should be inspected periodically and all the forgein object should be removed.

If the objects are allowed to remain in the tubeless tyre they tends to enlarge the puncture and repair became more difficult. The chances of sudden tyre puncture leading to accident are reduced.

Radial Ply Tyre

The radial ply tyre have radial have plies running from bead to bead across the crown at right angle to rotation.

On the side walls the direction of these plies is radial and hence the name. In between these plies and tyre trads there are cord or breakers which run around the circumference.

The angle between the cords varies from 18 degree to 22 degree. The number of layers depends upon the material used, the lateral stiffness needed and the load on the tyre required to carry.

The construction of radial ply tyre reduces cornering wear and considerably increases the overall life of the tyre but is an expensive of the slightly harder ride at low speed.

The radial plies gives greater pliability and comfort but no directional stability which comes from breakers since they firmly restrict any lateral stretching of the tread.

These tyres are expensive compared to other tyre. But they have better fuel economy and quick response to steering, puncture resistance.

Cross Ply Tyre Construction (Bias Ply Carcass)

In the cross bias tyre construction the alternate layers of cords run in opposite diagonal directions. It is also known as cross bias tyre construction.

this type of tyres have better wear and road holding characteristics. But they must not be fitted on the front wheels only.

Fit radial tyres all round, or use cross ply on the front and radial ply tyre on the rear wheels, otherwise the concerning characteristic will be seriously impaired.

Belted bias type

It is combination of above two type ( Radial ply and belted bias type). The basic construction is the bias ply over which run a number of breaker belts.

Comparison of Radial and Cross Ply tyres

- Radial ply tyres have following advantages over cross ply tyre.

a) Lower rolling resistance and hystresis loss which means reduce power consumption.

b) Longer treade life – The extra life may be up to 100% in some cases. This is on account of two factors

In radial ply less heat build up

The radial ply tyre does not squirm as it meets the figure shows the print of two type of tyre on road which in cross ply there is sideways slip which increase tyre wear.

c) In radial ply sidewall flexibility and treads region stiffness more, the tendency of pattern grooves to slightly close in contact path area which is not in cross ply. Thus, the water removal efficiency and hance the braking efficiency on wet road is better in radial ply.

d) More comfortable ride at high speeds.

e) Smaller slip angle and higher cornering power which gives better steering characteristic. The cornering force and self righting torque are higher for radial ply tyre.

f) During turning, a radial ply tyre has less tendency to distort and lift off the road from one side. Thus, there is better contact of tyre and hence less tendency to skid while cornering in radial tyre,

- Disadvantages of radial ply over cross ply tyre

a) Heavier steering at low speed

b) Uncomfortable ride at low speed

c) Instability during cornering

Factor affecting tyres life

The life of tyre is greatly reduced by underinflection, rapid stop, fast acceleration, road surface, misalignment and unbalance condition.

Tyres wear quickly on sand and gravel roads whereas the tyre life is promoted to its maximum value by the concrete and asphalt roads. In addition to normal wear caused by evenly and smoothly worn tread.

The Other type of tyre wears are over wear over inflation wear, under inflection, toe-in, toe-out, camber and cornering wear overloading of vehicle etc.

The above factor are explain briefly as follows

1) Under-inflection is the most usual cause of reduce tyre life. This cause the side of the tyres of its walls bend sharply as the wheel revolve. The cords eventually brake and the tyre blows out with the further revolving of the wheel. Tyre wear at the centrally excetrively and less on outer edge.

2) The tyre life diminishes with the increase of car speed. Fast starts, quick stop, high speed running or turning greatly reduce the tyre life while maximum tyre life and economy is promoted by conservative driving habits.

3) Due to overloading of the tyre, the cord structure of the side walls of a tyre is seriously flexed or over flexed reducing its life. This results more stress on the cords and greater temperature rise which cause the separation of pilies with weakening of the structure.

4) Due to excessive and to much camber the outer ribs will get warnt out. The wear on the inner side of the tyre treads is caused by the negative camber. The excessive wear on both the inner and outer area of the treads is caused due to excessive skidding on turn.

5) Due to toe in, toe out will affect the tyre life the scrubbing action on the road surface resulting in excessive wear if the toe in or toe but is not correct.

6) Careless mounting/demounting of tyre causes bead damage exposing the bead wire.

FAQ

What is the main function of the tire?

A tire has 3 basic functions: transport, guide and transmit. Transport the load resulting from the weight of the vehicle and all the overloads linked to the dynamic movements of the vehicle, as well as the aerodynamic overloads at high speed, absorbing at the same time the irregularities of the road.

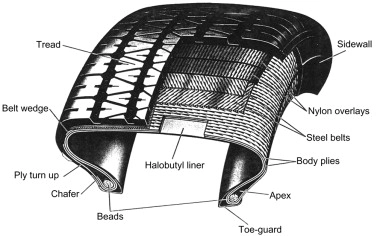

What are the 7 parts of a tire?

Tires are made up of many different parts and it is important to understand how they work.

A. Belts.

B. Lamellae.

C. Footprint.

D. Grooves.

E. Shoulder.

F. Side wall.

G. Inner lining.

What is the benefit of the tire?

And for good reason: the tire’s sidewall and tread are independent of each other thanks to radial ply chords, allowing great flexibility while still maintaining vehicle stability. In turn, this helps absorb shock and increases overall comfort. The tire itself also has lower fuel consumption than other types.

What are the tires made of?

Tires are made of up to 30 different types of rubber, antioxidants, textile elements, steel belts, beads, and other components. Natural and synthetic rubber combine to form the core component of your tire.

How much rubber is in a tire?

Truck tires typically contain 30% natural rubber, car tires about 15%.

You may also like

External Link