Table of Contents

What is proximity sensor

A proximity sensor is a device that is used to detect the presence or absence of an object within a certain range without any physical contact. It measures the distance between the sensor and the object by emitting electromagnetic fields, infrared radiation, or ultrasound waves and analyzing the reflection or absorption of those signals.

Proximity sensors are commonly used in various applications, including mobile devices, industrial automation, robotics, automotive systems, and security systems. They are used to perform tasks such as object detection, motion sensing, and touchless control.

There are different types of proximity sensors available, each utilizing different technologies to detect objects. Here are a few common types:

Inductive Proximity Sensors: These sensors use an electromagnetic field to detect metallic objects. When a metallic object enters the sensor’s range, it alters the electromagnetic field, triggering a response.

Capacitive Proximity Sensors: These sensors use changes in capacitance to detect the presence of an object. When an object with a different dielectric constant enters the sensor’s range, it affects the capacitance, leading to detection.

Ultrasonic Proximity Sensors: These sensors use ultrasonic waves to measure the distance to an object. They emit high-frequency sound waves and measure the time it takes for the waves to bounce back after hitting an object.

Optical Proximity Sensors: These sensors use light, usually infrared, to detect the presence of an object. They emit light beams and measure the reflection or absence of the beams to determine the proximity of an object.

Proximity sensors have numerous applications, such as automatic door systems, touchscreens, object detection in robotics, liquid level detection, parking assistance systems, and many more.

What is proximity sensor – Working, Type, Application and More

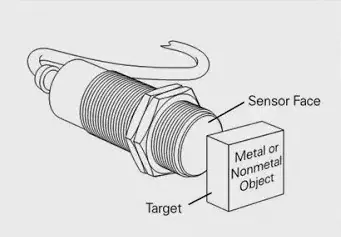

Inductive Proximity Sensors

Inductive proximity sensors are a type of proximity sensor that use electromagnetic fields to detect the presence of metallic objects within their detection range. These sensors are commonly used in industrial automation and manufacturing processes for various applications, including object detection, position sensing, and machine control.

How an inductive proximity sensor typically works

Operating Principle: An inductive proximity sensor consists of a coil of wire that is energized with an alternating current (AC). When the sensor is powered, it generates an electromagnetic field around the coil.

Detection Range: When a metallic object enters the detection range of the sensor, it interacts with the electromagnetic field. The presence of the metal causes a change in the field, which affects the sensor’s electrical properties.

Eddy Currents: When a metallic object enters the sensing field, it induces eddy currents in the object. These eddy currents create their own magnetic field, which opposes the original field generated by the sensor coil.

Signal Generation: The opposing magnetic field caused by the metal object affects the impedance of the sensor coil. This change in impedance results in a corresponding change in the sensor’s output signal.

Output Signal: The output signal of an inductive proximity sensor is typically binary, indicating the presence or absence of a metallic object within its detection range. When an object is detected, the sensor’s output is switched from a low state (no metal detected) to a high state (metal detected).

Sensing Range and Factors: The sensing range of an inductive proximity sensor depends on various factors, including the size, shape, and conductivity of the target object. Factors such as the coil diameter, operating frequency, and sensitivity settings of the sensor can also affect the sensing range.

Inductive proximity sensors offer advantages such as non-contact detection, robustness, and resistance to environmental factors like dirt, dust, and moisture. They are commonly used in industrial applications, including machine automation, assembly lines, material handling, and conveyor systems, where reliable and precise detection of metallic objects is required.

Application

Inductive proximity sensors have a wide range of applications in various industries due to their ability to detect metallic objects without physical contact. Here are some common applications of inductive proximity sensors:

Object Detection: One of the primary applications of inductive proximity sensors is object detection. They are used to detect the presence or absence of metallic objects in industrial automation settings. For example, in assembly lines, these sensors can detect the presence of components or parts to ensure proper positioning, orientation, or triggering of specific actions.

Position Sensing: Inductive proximity sensors can be used for position sensing applications. They can detect the position of metallic objects in machinery or conveyors, enabling precise control and monitoring of processes. For instance, they can be used to determine the position of a moving object, stoppers, or actuators in a manufacturing line.

Machine Control: Inductive proximity sensors play a crucial role in machine control applications. They can be used to monitor the position and movement of machine components such as doors, gates, or robotic arms. By detecting the presence or absence of objects, these sensors can trigger specific actions or provide feedback for safety and control purposes.

Metal Sorting and Identification: In industries where sorting and identification of metallic objects are required, inductive proximity sensors are employed. They can be used in recycling plants, material handling systems, or mining operations to sort and separate different types of metals based on their presence or absence.

Safety Systems: Inductive proximity sensors are utilized in safety systems to ensure the protection of personnel and equipment. For example, in industrial environments, they can be integrated into safety gates or barriers to detect the presence of objects and prevent accidents by triggering immediate stoppage of machinery or equipment.

Advantages and disadvantages

Inductive proximity sensors offer several advantages and disadvantages, which are important to consider when selecting and implementing them in different applications. Here are the main advantages and disadvantages of inductive proximity sensors:

Advantages

Non-contact Detection: Inductive proximity sensors can detect metallic objects without physical contact. This non-contact nature eliminates the need for mechanical components, reducing wear and tear and ensuring longer sensor lifespan.

High Reliability: Inductive proximity sensors are known for their high reliability. They are not affected by environmental factors such as dust, dirt, or moisture, making them suitable for use in harsh or dirty industrial environments.

Fast Response Time: These sensors provide rapid response times, typically in the range of microseconds, allowing for quick detection and response to changes in the proximity of metallic objects.

Wide Range of Sensing Distances: Inductive proximity sensors are available with varying sensing distances, allowing flexibility in different applications. They can detect metallic objects ranging from a few millimeters to several centimeters away, depending on the sensor type and model.

Simple Installation: Installing inductive proximity sensors is usually straightforward. They can be easily mounted in various orientations and integrated into existing systems without significant modifications or complex setup procedures.

Disadvantages

Limited Sensing Materials: Inductive proximity sensors can only detect metallic objects. They are not suitable for detecting non-metallic materials such as plastic, wood, or liquids. If the application requires detection of non-metallic objects, alternative sensor types should be considered.

Sensitivity to Material Composition: The sensing distance and performance of inductive proximity sensors can be affected by the composition and conductivity of the metallic object being detected. Certain materials may reduce the sensing range or accuracy of the sensor, requiring careful selection and testing.

Sensing Angle Limitations: Inductive proximity sensors have a limited sensing angle, typically around 90 degrees. They are most sensitive to objects located directly in front of the sensor and may have reduced sensitivity to objects at extreme angles or off-center positions.

Electrical Interference: Inductive proximity sensors can be susceptible to electromagnetic interference (EMI) from nearby electrical equipment or power lines. Care must be taken to minimize potential interference sources and ensure proper grounding and shielding to maintain reliable sensor operation.

Cost: Compared to some other types of proximity sensors, inductive proximity sensors can be relatively more expensive. The cost consideration may be a factor when implementing these sensors in large-scale or cost-sensitive applications.

What is proximity sensor – Working, Type, Application and More

Capacitive Proximity Sensors

Capacitive proximity sensors are a type of proximity sensor that detect the presence or absence of objects based on changes in capacitance. They are commonly used in various industries and applications where non-metallic objects need to be detected. Here’s an overview of capacitive proximity sensors:

Operating Principle

Capacitive proximity sensors work based on the principle of capacitance. Capacitance is the ability of an object to store electrical charge. When a capacitive proximity sensor is powered, it generates an electrostatic field around its sensing area.

Detection Method

When a non-metallic object enters the sensing range of a capacitive proximity sensor, it disrupts the electrostatic field, altering the capacitance of the sensor. This change in capacitance is detected by the sensor, triggering an output signal indicating the presence of the object.

Sensing Range

The sensing range of a capacitive proximity sensor depends on factors such as the size and dielectric constant of the target object. The dielectric constant represents the object’s ability to store electrical charge. Objects with higher dielectric constants have larger effects on the capacitance of the sensor and can be detected from a greater distance.

Applications

Liquid Level Sensing: Capacitive proximity sensors are widely used for liquid level sensing in tanks or containers. They can detect the presence or absence of conductive or non-conductive liquids, such as water, oil, or chemicals. By measuring the change in capacitance caused by the liquid, these sensors provide accurate level measurements.

Object Detection: Capacitive proximity sensors are employed in applications where non-metallic objects need to be detected, such as plastic, glass, paper, or textiles. They are used in packaging, material handling, and assembly lines to detect the presence of objects, ensuring proper positioning, sorting, or triggering of processes.

Touch and Gesture Sensing: Capacitive proximity sensors are commonly found in touchscreens and touch-sensitive interfaces. They can detect the proximity of a finger or stylus without physical contact, allowing for touch input and gesture recognition in devices like smartphones, tablets, and interactive displays.

Human Presence Detection: Capacitive proximity sensors can detect the presence of a person in various applications, including occupancy detection in buildings, home automation systems, and security systems. They can be used to trigger actions such as turning on lights, activating alarms, or adjusting settings based on human presence.

Advantages and Disadvantages

Advantages

Can detect both conductive and non-conductive objects.

Immune to environmental factors such as dust, dirt, and moisture.

Can operate in non-metallic or conductive environments.

Can detect objects without physical contact.

Disadvantages

Sensitive to changes in humidity and temperature, which may affect accuracy.

Sensing range can be influenced by the dielectric constant and size of the detected object.

Subject to false triggers if not properly calibrated or shielded in noisy environments.

Overall, capacitive proximity sensors are valuable in applications where the detection of non-metallic objects or liquid levels is required. Their ability to work without physical contact makes them versatile in various industries, ranging from automation and robotics to consumer electronics and industrial processes.

What is proximity sensor – Working, Type, Application and More

Ultrasonic Proximity Sensors

Ultrasonic proximity sensors are a type of proximity sensor that use ultrasonic waves to detect the presence or absence of objects within their range. They emit high-frequency sound waves and analyze the reflected waves to determine the distance to the object. Ultrasonic proximity sensors have numerous applications in various industries. Here’s an overview of their operation and applications:

Operating Principle

Ultrasonic proximity sensors work based on the principle of sound wave reflection. The sensor emits high-frequency ultrasonic waves, typically in the range of 20 kHz to 200 kHz, and measures the time it takes for the waves to bounce back after hitting an object. By knowing the speed of sound in the medium, the sensor calculates the distance to the object.

Detection Method

When the ultrasonic waves emitted by the sensor encounter an object, they reflect off its surface. The sensor then detects the reflected waves using a receiver. By measuring the time delay between the emission and reception of the waves, the sensor determines the distance to the object.

Sensing Range

The sensing range of ultrasonic proximity sensors depends on various factors, including the power and frequency of the emitted waves, as well as the sensitivity of the receiver. Ultrasonic sensors can typically detect objects ranging from a few centimeters up to several meters away, depending on the sensor’s design and specifications.

Applications

Object Detection and Distance Measurement: Ultrasonic proximity sensors are commonly used for object detection and distance measurement in industrial automation and robotics. They can detect the presence or absence of objects in assembly lines, conveyor systems, and robotic applications. They can also provide precise distance measurements for positioning or obstacle avoidance.

Parking Assistance Systems: Ultrasonic proximity sensors are utilized in automotive applications, particularly in parking assistance systems. They help drivers gauge the distance between their vehicle and obstacles while parking, providing audio or visual feedback to prevent collisions.

Level Sensing and Liquid Measurement: Ultrasonic proximity sensors are employed in liquid level sensing applications. They can measure the distance to the liquid surface in tanks or containers, allowing for accurate level measurements. They are widely used in industries such as water management, chemical processing, and storage facilities.

Proximity Sensing in Consumer Electronics: Ultrasonic proximity sensors are integrated into various consumer electronics devices. For example, they are used in smartphones to detect the presence of a user’s ear during a call, automatically turning off the display to save power and prevent unintended touch input.

Advantges and Disadvantages

Advantages

Non-contact detection: Ultrasonic proximity sensors do not require physical contact with the object being detected.

Wide sensing range: They can detect objects at various distances, depending on the sensor’s specifications.

Versatile: Ultrasonic sensors can detect both solid and liquid objects, making them applicable in a range of industries.

Disadvantages

Affected by environmental conditions: Factors like temperature, humidity, and air density can affect the accuracy of ultrasonic measurements.

Beam spreading: Ultrasonic waves can spread and diverge, leading to a wider detection area, which may require careful calibration and positioning.

Potential interference: Ultrasonic sensors may experience interference from reflective surfaces or other ultrasonic sources in the environment.

Ultrasonic proximity sensors offer reliable and accurate object detection and distance measurement capabilities, making them valuable in various industrial, automotive, and consumer electronics applications.

What is proximity sensor – Working, Type, Application and More

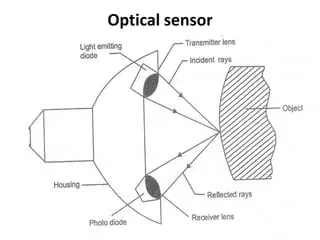

Optical Proximity Sensors

Optical proximity sensors, also known as photoelectric sensors, are electronic devices that use light to detect the presence or absence of objects within their range. These sensors emit light beams and analyze the reflection or absence of the beams to determine the proximity of objects. Optical proximity sensors have various types and applications. Here’s an overview of optical proximity sensors:

Operating Principle

Optical proximity sensors work based on the principle of light detection. They consist of a light source (usually infrared), a receiver, and associated circuitry. The light source emits a beam of light, and the receiver detects the reflected or interrupted light. The presence or absence of the reflected or interrupted light is used to determine the proximity of objects.

Types of Optical Proximity Sensors

Reflective Type: In reflective optical proximity sensors, the light source and receiver are housed in the same unit. The emitted light beam is reflected back to the receiver by the target object or a reflective surface. The presence or absence of the reflected light is used to detect the object’s proximity.

Through-beam Type: Through-beam optical proximity sensors consist of a separate light source and receiver, placed opposite each other. The light beam is emitted from the source and detected by the receiver. The presence of an object between the source and receiver interrupts the light beam, indicating the object’s proximity.

Diffuse Type: Diffuse optical proximity sensors have a combined light source and receiver in a single unit. The emitted light beam is directed towards the object, and the receiver detects the reflected light. The proximity of the object is determined based on the intensity of the reflected light.

Applications

Object Detection: Optical proximity sensors are commonly used for object detection in various industries. They can detect the presence or absence of objects on assembly lines, conveyor systems, packaging machines, and other automation applications.

Distance Measurement: Some optical proximity sensors can be used for distance measurement. By measuring the intensity or time of flight of the reflected light, they can provide accurate distance information.

Liquid Level Sensing: Optical proximity sensors can be employed for liquid level sensing in tanks or containers. They detect the presence or absence of liquid by analyzing the reflection of the emitted light beam.

Edge and Line Detection: Optical proximity sensors can be used to detect edges or lines on objects or surfaces. They can provide precise positioning information for alignment, sorting, or inspection processes.

Presence Sensing: Optical proximity sensors are used in safety applications to detect the presence of humans or objects in hazardous areas. They can trigger safety systems or stop machinery to prevent accidents.

Advantages and Disadvantages

Advantages

Non-contact detection without physical contact with objects.

Versatile detection of various objects, including non-metallic and transparent materials.

Fast response times for real-time applications.

Suitable for use in clean and controlled environments.

Disadvantages

Susceptible to ambient light interference.

Limited sensing range compared to some other sensor types.

Reflectivity and surface characteristics of objects can affect detection accuracy.

Optical proximity sensors offer reliable object detection capabilities in a range of applications. Their non-contact operation, versatility, and fast response times make them widely used in industrial automation, robotics, packaging, and safety systems.

You may also like