Table of Contents

Ram cylinder

When piston is larger and almost equal to the piston rod, it is known as ram cylinder.

A ram cylinder, also known as a single-acting hydraulic cylinder or a push cylinder, is a type of hydraulic actuator that converts hydraulic pressure into linear mechanical force in one direction. It consists of a cylindrical barrel, a piston, and a rod.

How a ram cylinder operates

Construction: A ram cylinder consists of a cylindrical barrel that houses a piston and a rod. The barrel is sealed at one end, while the other end has an opening for the rod to extend and retract.

Hydraulic fluid entry: Hydraulic fluid, usually oil, is supplied to the cylinder through an inlet port. The fluid enters the cylinder and applies pressure on one side of the piston.

Piston movement: The hydraulic pressure forces the piston to move in the direction of the hydraulic force, pushing the rod outward from the cylinder. The rod extends as the piston moves, providing the linear mechanical force.

Rod retraction: The rod can be retracted either by an external force or by the use of gravity. When the hydraulic pressure is released or reversed, the piston moves back to its initial position, causing the rod to retract into the cylinder.

Key features and considerations of ram cylinder

Single-acting operation: Ram cylinders are single-acting, meaning they exert force in only one direction (usually the extension direction) and rely on external forces or gravity for retraction. This characteristic makes them simpler in design and operation compared to double-acting cylinders.

Force and stroke: The force and stroke capability of a ram cylinder depend on its size, pressure rating, and the area of the piston. These factors determine the maximum force the cylinder can exert and the distance the rod can travel.

Seal and lubrication: The piston and rod of a ram cylinder are equipped with seals to prevent leakage of hydraulic fluid. Proper lubrication and maintenance of these seals are important for ensuring smooth operation and longevity of the cylinder.

Mounting options: Ram cylinders can be mounted in various configurations, including flange-mounted, trunnion-mounted, or clevis-mounted, depending on the specific application requirements.

Ram cylinders provide a simple and efficient solution for applications that require linear force in a single direction. Their design simplicity and cost-effectiveness make them suitable for a wide range of industries and applications.

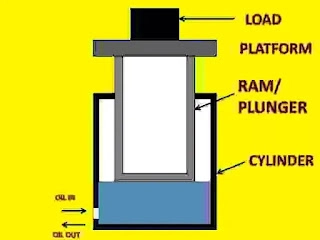

Construction of ram cylinder

It consists of cylinder in which ram Or plunger is mounted. The plunger is a larger size piston with d=l. Hence piston and piston rod are same as a single element.

The platform is provided at the top of the ram for placing the heavy loads conveniently.

The single inlet is provided in the cylinder for oil feed. The r is always mounted vertically. It is single acting type.

Working

When pressurised oil enter through inlet, it will lift the ram in the upward direction. The load is lifted to the required height.

When oil supply is cut off to lower the load, the ram come downward die to gravity force and oil is drained to the tank through the outlet port.

Symbol

Advantages and Disadvantages

Advantages

Simple design: Ram cylinders have a straightforward design with fewer moving parts compared to other types of hydraulic cylinders. This simplicity makes them easier to install, operate, and maintain.

Cost-effective: Due to their simple construction, ram cylinders are generally more cost-effective compared to other hydraulic cylinders. They are often a preferred choice when budget constraints are a consideration.

Compact size: Ram cylinders tend to be more compact in size compared to other types of cylinders with the same force capabilities. This makes them suitable for applications where space is limited or where a smaller footprint is desired.

High force output: Ram cylinders can generate high force output due to their large piston area. They are commonly used in applications that require substantial pushing or pressing force, such as in construction, agriculture, and material handling.

Disadvantages

Limited functionality: Ram cylinders are single-acting, meaning they exert force in one direction only. They rely on external forces or gravity for retraction, which limits their functionality in applications requiring bidirectional force.

Slower retraction speed: Since the retraction of the rod is not powered by hydraulic pressure, the retraction speed of a ram cylinder is generally slower compared to double-acting cylinders. This can impact the overall cycle time and efficiency of certain applications.

Limited stroke length: The stroke length of a ram cylinder is determined by the length of the cylinder barrel and the rod. This limited stroke length can be a disadvantage in applications that require long extension or retraction distances.

External retraction mechanism required: To retract the rod of a ram cylinder, an external force or gravity needs to be employed. This may require additional equipment or mechanisms, which can add complexity and cost to the overall system.

It’s important to consider these advantages and disadvantages in relation to the specific requirements of the application when choosing whether to use a ram cylinder.

Application

Commonly used as a lift in a automobile service station.

Material handling: Ram cylinders are widely used in material handling equipment, such as forklifts, pallet jacks, and scissor lifts. They provide the necessary force to lift and lower loads, extend and retract lifting arms or forks, and perform pushing or pulling actions in loading and unloading operations.

Construction equipment: Ram cylinders are employed in construction machinery, including excavators, backhoes, and bulldozers. They assist in tasks such as digging, lifting heavy objects, pushing or pulling loads, and controlling attachments like buckets or blades.

Agricultural machinery: Ram cylinders play a vital role in agricultural equipment, such as tractors, harvesters, and sprayers. They are used in various applications, including raising and lowering implements, operating hydraulic arms, adjusting the height or angle of equipment, and controlling hydraulic mechanisms for seed distribution or crop spraying.

Industrial presses: Ram cylinders are utilized in industrial presses, such as hydraulic presses, stamping machines, and metal forming equipment. They generate the force needed to press materials together, shape metal sheets or components, and perform precision operations in manufacturing processes.

Waste management systems: Ram cylinders are integral to waste compactors and trash compactors used in waste management systems. They provide the force required to compress and compact waste materials, reducing their volume for efficient disposal or transportation.

Automotive applications: Ram cylinders find application in automotive systems, including hydraulic jacks, vehicle lifts, and vehicle braking systems. They enable lifting vehicles for maintenance or repair, assist in vehicle suspension, and operate hydraulic brakes for effective stopping power.

FAQ

What is a ram cylinder?

A ram cylinder is a type of hydraulic cylinder that acts as a ram. A hydraulic ram is a device in which the cross-sectional area of the piston rod is more than half the cross-sectional area of the moving components.

How does a ram cylinder work?

In principle, a hydraulic ram works by pumping an external fluid into both sides of a cylinder simultaneously, this creates a high and low pressure side within the cylinder depending on the load it is trying to move.

What material are ram cylinders made of?

Common materials used are high strength steel, ductile iron, carbon steel, stainless steel and aluminum. Seals: Pressure characteristics, durability, and ambient or operating temperatures help influence the size and type of seals incorporated.

You may also like