Table of Contents

Double rod double acting cylinder

When piston rod is provided on both side of the piston, it is called as double piston rod double acting cylinder.

A double rod double-acting cylinder is a type of hydraulic or pneumatic cylinder that features two piston rods extending from both ends of the cylinder. This design allows for bidirectional force and motion, with the ability to apply force in both directions (push and pull).

Construction of Double rod double acting cylinder

It consists of cylinder body with end covers, the piston is fitted with piston seals.

The piston rod is extended and provided on both side of the piston. Hence area on both side of the piston is same.

Two Piston Rods: As the name suggests, these cylinders have two piston rods—one extending from each end of the cylinder. This design offers balanced forces and reduces the risk of side loading.

Double-Acting: The cylinder is double-acting, meaning it can apply force or move in both directions. It can extend and retract under hydraulic or pneumatic pressure.

Balanced Force: Having two piston rods helps distribute the force evenly on both sides of the piston. This results in reduced side loading and increased stability, making these cylinders suitable for applications where precise control and balance are required.

Versatile Applications: Double rod double-acting cylinders are used in various industrial applications where control of force, speed, and direction is essential. They are commonly found in manufacturing, automation, construction, and many other industries.

Customizable Stroke Length: The stroke length of these cylinders can often be customized to meet the specific requirements of the application.

Hydraulic or Pneumatic Operation: These cylinders can be operated using hydraulic fluid or compressed air, depending on the specific application’s requirements.

Cylinder Types: Double rod double-acting cylinders are available in various designs, including tie-rod cylinders, welded cylinders, and other configurations to suit different needs.

Mounting Options: They can be mounted in different ways, such as on a fixed structure or as part of a mechanical system.

Working

A double-rod, double-acting cylinder is a type of hydraulic or pneumatic cylinder commonly used in various industrial and mechanical applications. It features two rods on both sides of the piston, and it can generate force and motion in both directions.

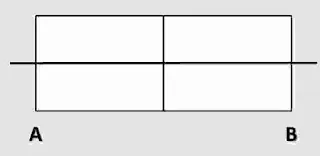

When oil enters through inlet port A, it pushes the piston to complete forward stroke by draining the oil from the other port B.

When oil enters through inlet port B, it moves the piston to complete return stroke by draining the oil from the other port A.

As the area on both side of piston is same, it produces equal forces in both directions.

The area on both side is,

a= π/4(D-d)

D = Diameter of cylinder bore

d= Diameter of piston rod

What is Double rod double acting cylinder | Construction, Working

Cylinder Body: The cylinder body is typically a cylindrical tube or barrel that contains the piston, rods, and seals. It is often made of materials like steel or aluminum to withstand pressure and provide stability.

Piston: Inside the cylinder body, there is a piston that separates the cylinder into two chambers: the front and the rear. The piston is usually made of a material like metal and is sealed to the cylinder walls to prevent fluid from leaking between the chambers.

Rods: A double-rod cylinder has two rods attached to the piston, one on each side. These rods extend out of both ends of the cylinder body. These rods are typically made of a strong and durable material like steel.

Fluid Supply: To operate the cylinder, a hydraulic or pneumatic fluid (typically oil or compressed air) is supplied to the cylinder through ports. The fluid enters one of the two chambers, either the front or the rear chamber, depending on the desired direction of movement.

Double-Acting Operation: The “double-acting” part of the cylinder’s name refers to its ability to generate force in both directions. When fluid is supplied to one chamber, it pushes the piston and attached rod in one direction, extending the rod from one end. Simultaneously, the fluid in the other chamber is typically allowed to exit or is returned to a reservoir.

What is Double rod double acting cylinder | Construction, Working

Reversing Direction: To reverse the direction of motion, fluid is supplied to the opposite chamber, pushing the piston and the other rod in the opposite direction. This extends or retracts the other rod while the first rod remains stationary or retracts further.

Control Valves: The direction and speed of the cylinder’s movement are controlled by various control valves that regulate the flow and pressure of the hydraulic or pneumatic fluid entering and exiting the cylinder. These valves can be manually operated, electrically controlled, or computer-controlled, depending on the application’s requirements.

End Stops: The ends of the cylinder often have end stops or cushions to prevent the piston from impacting the cylinder ends with excessive force. These help protect the cylinder and the connected components.

Symbol

Application

It is used in table movement of grinding machine.

It is useful in robotic mechanisms where the rod is clamped at both ends and the body moves.

Material Handling: These cylinders are frequently used in material handling equipment, such as conveyor systems, to move, lift, or manipulate objects. The double rod design provides balanced forces, allowing for precise control.

Industrial Machinery: Double rod double-acting cylinders find use in various industrial machines, including metal forming machines, stamping presses, and plastic injection molding machines. They help control the motion and force required in these processes.

Robotics: In robotic applications, these cylinders are used to control the movement of robotic arms, grippers, and end-effectors, providing both pushing and pulling actions. This enhances the versatility and precision of robotic movements.

Construction and Civil Engineering: Double rod double-acting cylinders are used in construction machinery, such as cranes and loaders, to lift and position heavy loads. They are also used in pile drivers and excavators for digging and driving piles.

Automotive Industry: In automotive manufacturing, these cylinders play a role in processes such as vehicle chassis assembly, painting, and welding, where precise control and flexibility in both directions are required.

Aerospace: In the aerospace industry, double rod double-acting cylinders are used in applications like landing gear, wing flaps, and cargo door operations.

Packaging Machinery: Packaging and labeling machines use these cylinders for tasks such as sealing, labeling, and filling containers.

Agricultural Equipment: In agricultural machinery like tractors and plows, double-acting cylinders are used to control functions like raising and lowering implements, steering, and adjusting the position of attachments.

Oil and Gas Industry: They are used in drilling equipment, wellhead control systems, and pipeline maintenance for various tasks involving controlled movement and force.

Advantages and Disadvantages of Double rod double acting cylinder

Advantages

Bi-directional Force: The primary advantage of a double-rod double-acting cylinder is its ability to generate force in both directions. This makes it suitable for applications where you need to push and pull objects or perform tasks in both directions.

Precise Positioning: These cylinders allow for more precise positioning of the load due to their two rods, which can be controlled independently. This is particularly useful in applications where fine control of movement is essential.

Increased Stability: The two rods provide increased stability and reduce the likelihood of side-loading issues compared to single-rod cylinders. This can result in longer cylinder and seal life.

Balanced Forces: The double-rod design helps balance the forces on either side of the piston, reducing the chances of bending or deflection of the piston rod.

Flexibility: Double-rod cylinders can be used in various applications, including clamping, lifting, pushing, and pulling, making them versatile components in many industrial processes.

Disadvantages

Complexity: Double-rod double-acting cylinders are more complex and have more components than their single-rod counterparts. This complexity can increase manufacturing and maintenance costs.

Cost: As mentioned, the additional components and materials used in the double-rod design can make these cylinders more expensive compared to single-rod cylinders.

Size and Weight: Double-rod cylinders are typically larger and heavier than single-rod cylinders with the same bore size. This can be a disadvantage in applications where space and weight are critical factors.

Maintenance: With more components and seals, double-rod cylinders may require more frequent maintenance compared to simpler cylinder designs.

Potential for Leaks: The presence of additional seals and connections in double-rod cylinders increases the risk of hydraulic or pneumatic fluid leaks, which can lead to reduced performance and environmental concerns.

FAQ

What is double acting double rod cylinder?

A double rod double-acting cylinder is a type of hydraulic or pneumatic cylinder that features two piston rods extending from both ends of the cylinder.

What is the double rod cylinder for?

This particular type of cylinder has a piston rod connected to each of the piston faces. Double rod cylinders are useful for moving two loads simultaneously and also eliminate the differential area between the rod side and the blind side of the piston.

You may also like