Table of Contents

Final drive

In a vehicle two half axle shafts rotate the driving wheel. These acle shafts are located at 90 degree to the longitudinal centre line of an automobile vehicle.

when power transmission is affected by a propeller Shaft from the front to rear, the half axle shaft are at 90 degree to the propeller shaft. So for transmitting the power at 90 degree a pair of gears is used. This pair of gear is known as final drive.

The final drive consist of a bevel pinionand a crown wheel or worm and wheel arrangement. The bevel pinion is connected to a propeller Shaft through a universal joint. From the crown wheel the drives goes to differential.

Necessity of final drive

In an automobile vehicle, if the propeller shaft is geared rigidly to both the driving wheels, then both the wheels will be rotated at the same speed.

When the vehicle is driven on straight road, there will be no any problem. But when vehicle take turn or on a bumper road, the right and left side wheel of the vehicle will have to cover different distance I. e. outer wheel must travel larger than the inner Wheel.

When the propeller shaft drives the inner and outer wheels, at one of the driving wheel will tends to slip on the road because of this tyre wear quickly caused wheel skidding and wheel cannot controlled in turn.

Propeller Shaft

The propeller shaft connect the transmission shaft to the bevel pinion shaft of differential at the wheel axle. It is also called as drive shaft.

Functions of the propeller shaft

It transmit rotary motion of the gear box output shaft to the differential and them to the wheels through the axle shaft.

Propeller shaft transmits motion at an angle which is varying frequently.

It adjust the change in length between gear box and rear axle.

The differential unit consists of

The term “differential unit” typically refers to the differential mechanism in a vehicle’s drivetrain.

The differential is a critical component that allows the wheels on an axle to rotate at different speeds while still receiving torque from the engine.

This is essential when a vehicle is turning, as the wheels on the outside of the turn need to cover a greater distance and rotate faster than the wheels on the inside.

The main components of a typical differential unit include:

Differential Housing:

This is the outer casing that encloses the differential assembly. It provides support and protection to the internal components.

Ring Gear and Pinion:

The ring gear is a large gear mounted on the differential case, and the pinion gear is connected to the drive shaft. Together, they form a gear ratio that determines the rotational speed and torque applied to the wheels.

Differential Gears (Spider Gears):

These gears are located inside the differential housing and are responsible for allowing the wheels to rotate at different speeds during turns. The arrangement of these gears is often referred to as the spider gear set.

Axle Shafts:

Axle shafts extend from the differential assembly to the wheels. They transmit power from the differential to the wheels, allowing them to rotate.

Bearings and Seals:

Bearings support the rotating components, such as the differential gears, while seals help prevent fluid leakage from the differential.

Differential Fluid:

Differential fluid (gear oil) lubricates the internal components of the differential, reducing friction and dissipating heat.

Limited-Slip or Locking Mechanisms (Optional):

Some differentials may include limited-slip or locking mechanisms to improve traction and handling in certain conditions.

Housing Cover:

A cover on the rear of the differential housing provides access for maintenance and contains the lubricating fluid.

Construction and working

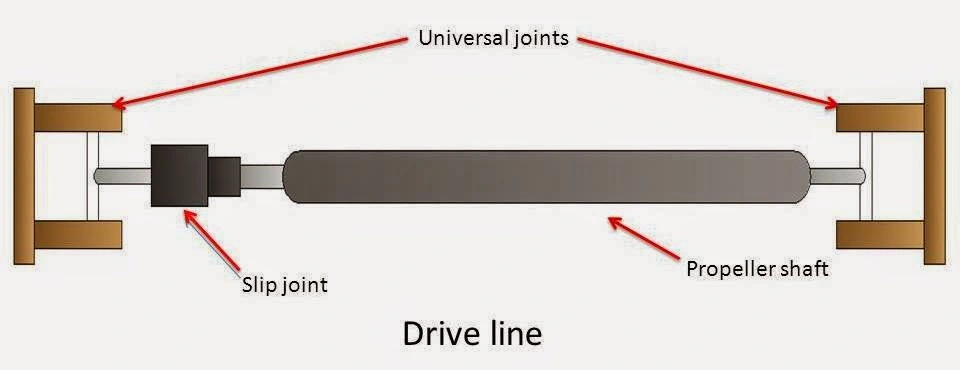

It is made of Steel Tube or hollow shaft and two type of flexible joint, namelya splpine sleeve( also called slip joint ) and two universal joint at each end.

The diameter usually range from 50 to 70 mm and the thickness range from 1.5 to 7.5 mm depending upon the type of application.

Tubular section makes them lighter and stronger than a solid shaft of the same size.

It is also less expensive.

The universal joint takes care of the variation in the inclination of the propeller Shaft during up and down movement of vehicle.

They also permit the motion to be transmitted from the gear box shaft to the bevel pinion shaft of the differential at all times irrespective of the inclination of the propeller shaft.

The slip joint serve to adjust the length of the propeller shaft when demanded by the rear axle movement.

The slip joint is formed by the internal splines on the sleeve attached to the universal joint at left and external spline on propeller shaft.

When the distance between the transmission shaft and the pinion shaft of differential is more as in truck and long chassis vehicles.

One or more intermediate propeller shaft is connected to the gear box output shaft and other end to the main propeller shaft.

The interediate propeller shaft is supported in bearing unit fixed to frame.

This arrangement avoid sagging and whirling of propeller shaft at critical whirling Speed. The whirling speed is decrease at the square of its length.

Differential

Differential is defined as an arrangement of a gear that permit one shaft to drive two other shaft which transmit equal torque, although the three shafts may be rotating at unequal speeds.

Function of Differential

It splits the power that received and send the same through the two half axle shaft to the driving wheels.

Differential allows the two wheels to turn by the same amount when vehicle goes straight path.

It allow the driving wheels to turn by different amount when vehicle goes on curved path and delivers same power to both the wheels.

The speed difference between the two wheels became possible because the two half axle shaft are not directly coupled to the crown wheel but are drive through bevel pinion and side gears. This gear system constitute a differential.

Construction of Differential

The differential consist of crown wheel two type of bevel gear, cage and spider or cross arm.

The road wheels are driven by two half axle shaft.

The side gear on the inner ends of each the half axle shaft.

The sun bevel gear and planet bevel gear are mesh with each other at right angle. The sun gears are freely mounted on the spider or cross arm. The case together with the bevel pinions is secured in the differential cage is bolted to the crown wheel of the final drive.

The differential cage has a bearing and its centre. This bearing is mounted on the left half axle shaft. This arrangement permit the differential cage to turn independently on the half axle shaft.

The crown wheel is mesh with curved teeth bevel pinion which is rotated by propeller shaft.

Working

The pinion driven by the propeller shaft, rotate the crown wheel. Since the differential cage is attached to the crown wheel it also rotate, when the cage rotate, the bevel pinion and the cross arm which carries them moves around the circle with the differential cage.

When the vehicle take a turn on curved surface. The inner wheel meets a higher resistance than the outer wheel and hence its rotation is slowed down.

The resistance at the Inner Wheel ( which is near to the centre of curvature) is more because of these wheels are required to do the same amount of work in a shorter distance which they travels.

Now the tooth load became unqual. Because of this bevel pinions tends to turn on their spindles. This turn causes the bevel pinion roll around the planet gear on the one of the two half axle shaft.

Due to this action more turning of the outer side gear than inner side gear thereby accelerates the same until equilibrium is restored.

Thus outer side gear shaft turn more rapidly than the inner wheels shaft. So outer wheel has to travel more distance as compared to inner wheel during the same interval of time.

Let N be the straight path speed of vehicle and n be the change of speed of both wheel, then speed of Inner Wheel is (N – n) and that of outer wheel is (N + n).

What is the difference between differential and final drive

The terms “differential” and “final drive” are related components in a vehicle’s drivetrain, and they work together to transmit power from the engine to the wheels.

Differential

The differential is a component located between the two drive wheels of a vehicle (typically the rear wheels in rear-wheel-drive or all-wheel-drive vehicles). It is part of the axle assembly.

The main function of the differential is to allow the wheels to rotate at different speeds while maintaining power distribution from the engine.

When a vehicle turns, the outer wheel travels a longer distance than the inner wheel. The differential allows for this speed difference, preventing binding or tire scrubbing.

Final Drive

The final drive refers to the last set of gears in the drivetrain that delivers power from the differential to the wheels.

In some vehicles, the terms “final drive” and “differential” are used interchangeably, but they technically refer to different components. The final drive encompasses the gears that further transmit power from the differential to the wheels.

FAQ

What is the final drive?

The final drive is an assembly of gears in the back axle of rear-wheel drive vehicles and in the front axle of front-wheel drive vehicles. The last set of gears in the drive train is the final drive.

What is the main function of differential?

The function of a differential is to transmit power from the engine to the axle that moves the wheels and allow the wheels to move at different speeds from each other.

What is difference between differential and final drive.

A differential is a usually a pair of gears or more that divide the power derived from the engine to the four wheels differently.

Final Drive is result obtained after application of different types of differentials. Depending on the number of differentials, cars are classified into all wheel drive and four wheel drive. The number of differentials and its usage yield different performances and power output of a car.

What is the function of the final drive and differential?

The final drive is that last part in a machine’s powertrain system, and subsequently, the final component for increasing torque through gear reduction or changing the direction of power flow.

Is differential and drive shaft the same?

Driveshaft – This is the first component in the driveline. It is connected to the transmission and begins the power transfer process that goes into the differential, axle shafts and wheels.

Differential – A differential will control power to the individual drive wheels on either side of the vehicle.

You may also like