Table of Contents

Wheel

The main function of wheel is to support the load of the vehicle and passengers and two resist the side force during turning called lateral load. The wheel also transmit engine driving talk and breaking torque to the type while driving and breaking called as track to load

Who invented the wheel

The invention of the wheel is attributed to various ancient cultures, and it’s challenging to pinpoint a single individual or civilization responsible for its creation.

The wheel is considered one of the most crucial inventions in human history, and it likely emerged independently in different regions.

The earliest evidence of wheeled vehicles comes from Mesopotamia (modern-day Iraq) around 3500 BCE. Sumerians in ancient Mesopotamia are often credited with some of the earliest known wheeled vehicles.

However, other ancient cultures, such as those in the Indus Valley and Central Europe, also developed wheeled transportation around the same time or slightly later.

Type of Automobile wheels

- Pressed steel discs

- Wheels with steel wire spokes

- Light alloy casting wheels

Pressed Steel Disk Wheel

Pressed steel disc wheels refer to a type of automotive wheel that is commonly used in various vehicles. These wheels are typically made by pressing and stamping steel sheets into the desired shape.

The resulting wheel is sturdy and cost-effective, making it a popular choice for many automobiles, especially in the budget or economy vehicle segment.

Construction and working of pressed Steel disk wheel

- Now a day these Wheels are widely used for cars.

- These are light, strong, cheap and resistance to accidental damage. This type of wheel consists of two parts, namely Rim and the disc member welded together.

- When the bead of the tyre is resting in the well, it is possible to pass the tyre over the opposite is of the rim.

- The seat of the rim where the tyre rests has 5 to 15 degree teper so as the tyre is inflated, the beads are forced up the taper to give a wedge fit with tubeless tyre, the taper help of make a good seal.

- The wheels are secured to the axle by 4 or 5 bolt spaced equally in a circle around the hub flanges.

- Some lots are provided in the wheel disc to allow the air to pass to the inner side for better cooling the brake drum inside.

- A hole in the rim serves to accommodate tube valve.

- A wheel constructed in two parts which when fastened together combines to form a rim having to fixed flanges is called a divided wheel.

Advantages and Disadvantages

Pressed steel disk wheels, also known as pressed steel rims or wheels, are commonly used in automotive applications. These wheels are made by pressing and forming a flat sheet of steel into the desired wheel shape. Like any other engineering solution, pressed steel disk wheels have their advantages and disadvantages.

Here are some of them:

Advantages:

Cost-Effective: Pressed steel wheels are generally more cost-effective to manufacture compared to other types of wheels, such as alloy wheels. This makes them a popular choice, especially in budget or economy vehicles.

Durability: Pressed steel wheels are known for their durability and ability to withstand various road conditions. They can handle heavy loads and are less prone to damage from potholes or other road hazards.

Repairability: If a pressed steel wheel is damaged, it can often be repaired more easily and at a lower cost compared to more complex wheel designs. This can be advantageous for cost-conscious consumers.

Weight: Pressed steel wheels are typically lighter than some alternative wheel materials, such as cast iron. This can contribute to improved fuel efficiency and overall vehicle performance.

Corrosion Resistance: Many pressed steel wheels are treated with coatings or finishes that provide corrosion resistance, extending their lifespan and maintaining their appearance.

Disadvantages:

Aesthetics: Pressed steel wheels are generally considered less aesthetically pleasing compared to alloy wheels. Alloy wheels offer more design flexibility, allowing for a wider range of styles and finishes.

Weight: While pressed steel wheels are lighter than some alternatives, they are often heavier than alloy wheels. The weight difference may be a consideration for those looking to optimize vehicle performance.

Limited Design Options: Pressed steel wheels offer fewer design options compared to alloy wheels. Alloy wheels can be cast or forged into more intricate and customizable shapes.

Heat Dissipation: Alloy wheels are known for their superior heat dissipation properties compared to pressed steel wheels. This can be important in high-performance or heavy-duty applications where heat buildup may be a concern.

Rust Formation: While many pressed steel wheels are treated for corrosion resistance, they can still be susceptible to rust formation over time, especially if the protective coatings are damaged.

Wire or spoke wheels

Wheels with steel wire spokes are a type of wheel design commonly used in bicycles and motorcycles, as well as some vintage and classic cars. The spokes are thin, tensioned steel wires that radiate from the wheel hub to the wheel rim, forming a pattern that provides structural support and strength to the wheel.

Construction and Working

- These wheels are lighter, stronger and springy.

- It consist of a separate hub which is attached to rim through number of wire called spokes. These spokes are mounted in a complicated criss- cross fashion in all the three plane.

- The component of vehicle weight in the direction of spokes above hub is sustained by these spokes in tension. The braking and driving torque are taken by spokes.

- The side forces during cornering are taken by the spokes forming triangular arrangement.

- The initial tension in the spokes can be adjusted by screw nipples which also serve to secure the spokes to the rim.

- The hub is provided with internal spline to corresponding spline on axle shaft.

Advantages

These are light weight and high strength.

It provide better cooling of the brake drum due to better air flow around the brake drum and heat dissipated capacity.

It is very easy for changing the wheel as only one nut has to be opened.

Disadvantages

These are difficult to clean.

Spoked tend to work loose in service.

As rim has a hole for nipples, it is not possible to fit tubeless tyre.

These are expensive due to complicated in construction.

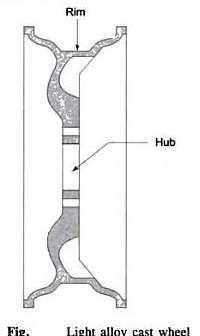

Cast light alloy wheel

A cast light alloy wheel refers to a type of wheel for vehicles that is made through a casting process using light alloys.

Light alloys are metals or metal alloys that have a lower density compared to steel, making them lighter. Common materials used for cast light alloy wheels include aluminum and magnesium alloys.

The casting process involves melting the alloy and pouring it into a mold to create the desired wheel shape. This method is often used because it allows for intricate designs and is cost-effective for mass production.

The resulting cast wheels are generally lighter than traditional steel wheels, which can contribute to improved fuel efficiency and overall vehicle performance.

Construction and Working

- Cast alloy wheels are made from casting of light alloy of aluminium or magnesium.

- They have wider rims and radial ribs which also acts as an angled spokes to provide strength and air circulation also reduce noise and vibration. Wider rims are provide stability during cornering.

- Stoveenameling of alloy improve appearance and provide corrosion resistance property.

- Cast wheels are generally used for car while forged wheels are preferred for heavy vehicles. Heavier section of wheel can be used which improve the stifness and result in better stress distribution

Cast light alloy wheel Advantages and Disadvantages

Light alloy wheels, commonly known as alloy wheels or rims, are made from a combination of metals such as aluminum and magnesium. These wheels have become popular in the automotive industry for various reasons.

Some advantages and disadvantages of cast light alloy wheels:

Advantages:

Weight Reduction: One of the primary benefits of alloy wheels is their lighter weight compared to traditional steel wheels. Lighter wheels can contribute to improved fuel efficiency and overall vehicle performance.

Aesthetics: Alloy wheels are often chosen for their aesthetic appeal. They come in a variety of designs and finishes, allowing for customization and enhancing the visual appeal of a vehicle.

Heat Dissipation: Alloy wheels have better heat dissipation properties compared to steel wheels. This can be particularly beneficial in high-performance vehicles or during heavy braking, as it helps prevent brake fade.

Handling and Performance: The reduction in unsprung weight (weight not supported by the vehicle’s suspension) can lead to improved handling and responsiveness. The vehicle may feel more agile and easier to control.

Corrosion Resistance: Aluminum alloys used in alloy wheels are more resistant to corrosion than steel. This makes alloy wheels less susceptible to rust and other forms of deterioration due to exposure to the elements.

Disadvantages:

Cost: Alloy wheels are generally more expensive to manufacture than traditional steel wheels. This cost is often reflected in the higher price of vehicles equipped with alloy wheels.

Durability: While alloy wheels are durable, they may be more prone to damage such as bending or cracking compared to steel wheels, especially in harsh driving conditions or if they encounter potholes or curbs.

Repair Costs: Repairs to alloy wheels can be more expensive than those for steel wheels. Additionally, some damages may be more challenging to repair, leading to the need for replacement.

Harsher Ride: In some cases, alloy wheels may result in a slightly harsher ride compared to steel wheels. This is because the reduced mass may transmit more road vibrations to the vehicle’s suspension.

Winter Performance: Alloy wheels can be less effective in harsh winter conditions, particularly if they are not properly cared for. They may be more susceptible to damage from road salt, and their metal composition can make them prone to corrosion in colder climates.

Interesting Facts About The Wheel

The wheel is one of the most important inventions in human history, revolutionizing transportation and machinery.

Some interesting facts about the wheel:

Ancient Origin:

The wheel was likely invented around 3500 BC in Mesopotamia (modern-day Iraq). The earliest known wheel and axle combination was found in Ur, dating back to this period.

Not Just for Transportation:

While wheels are commonly associated with transportation, they have been used for various purposes throughout history. In addition to carts and chariots, wheels have been employed in pottery, irrigation devices, and even early mechanical clocks.

Symbol of Progress:

The wheel is often used as a symbol of progress and innovation. It is a central motif in many flags, logos, and emblems representing industry, transportation, and advancement.

Evolution of Spokes:

Early wheels were solid disks, and the addition of spokes came later. Spokes provided strength while reducing the overall weight of the wheel. This innovation made wheels more efficient and durable.

Chariots in Warfare:

The invention of the spoked wheel had a significant impact on ancient warfare. The use of chariots with spoked wheels made them lighter, faster, and more maneuverable on the battlefield.

Gears and Cogs:

The wheel’s principle is often extended to gears and cogs in machinery. Gears, essentially rotating wheels with teeth, are crucial components in many mechanical systems, including clocks, engines, and industrial machinery.

Inventions Inspired by the Wheel:

The concept of a wheel has inspired various other inventions, such as pulleys, which are wheels with a groove used to guide a rope or belt. Pulleys are essential in lifting and conveying systems.

The Water Wheel:

The water wheel, an ancient invention, utilized the power of flowing water to turn a wheel. This technology was used for grinding grain, sawing wood, and other mechanical tasks in pre-industrial societies.

Revolution in Transportation:

The wheel played a pivotal role in transforming transportation. Wheeled vehicles such as carts, chariots, and later, automobiles, dramatically improved the efficiency and speed of travel.

Ubiquitous in Modern Life:

Wheels are so ingrained in modern life that they are found in numerous everyday objects, from bicycles and cars to shopping carts and office chairs. The wheel’s design and principles continue to influence contemporary engineering and design.

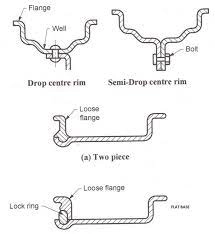

Type of Rim, their construction and working

What is Rim ?

Rim is well type of structure in which the tyre is contained.

Type

The rim are generally of two types

- Drops Centre Rim

- Flat base rim.

Construction and Working

- Drops Centre rims are generally widely used in two wheeler where as flat base rims are used in commercial vehicle. The rims are made of steel or aluminium.

- Also rim again classified into flat base 3 piece rim, semi drop centre and flat base divided type. For car tyre, well base or drop centre is the common tyre.

- The tyre is pressed into the racess of the drop centre well for laveling in opposite side over the rim flange. A slight tape is of 5 degree is provided for riding up the bead due to air pressure in the tyre.

- Flat base 3 piece rim is a detachable flange rim. It is used with stiff and heavy beads tyre fitted on heavy vehicles.

- The flange is held in position by a split lock ring similar to larger circlip. The lock ring may be removed after pushing the flange toward the tyres. Semi drops centre rim is a two piece rim. it is compromises between well base and flat base rim.

- It is suitable for light vehicle.

- It’s removal is simplified by split, detachable flange while the tyre is locked to the rim by a slight taper, when the tyre is removed the slight well mail be used.

- Flat base divided type rim used mainly on military vehicle. It is made in two halves which are bolted together by a ring of nut adjacent to the rim. For changing wheel these nuts should never be removed.

FAQ

Who when invented the wheel?

ancient Mesopotamian people

However, the ancient Mesopotamian people are widely believed to have invented the wheel around 4200–4000 BC, It is likely to have also been invented, independently in China, around 2800 BC.

How does a wheel work?

Wheels on cars and lorries are attached to a pole called an axle, which passes through the centre of the wheel. The engine spins the axle round and round, turning the wheel and moving the vehicle along.

What is wheel facts?

- A wheel is a disc- or circle-shaped device.

- A wheel allow things to roll.

- No wheels exist in nature.

- The first wheels were originally used by potters to help shape clay.

- The ancient Greeks invented the wheelbarrow.

- Wheels are used on Cars, Bikes, Buses, Ferris Wheel, Aeroplane wheels, and baby strollers.

Where do we use the wheel?

Wheels can be used for transportation.

You may also like