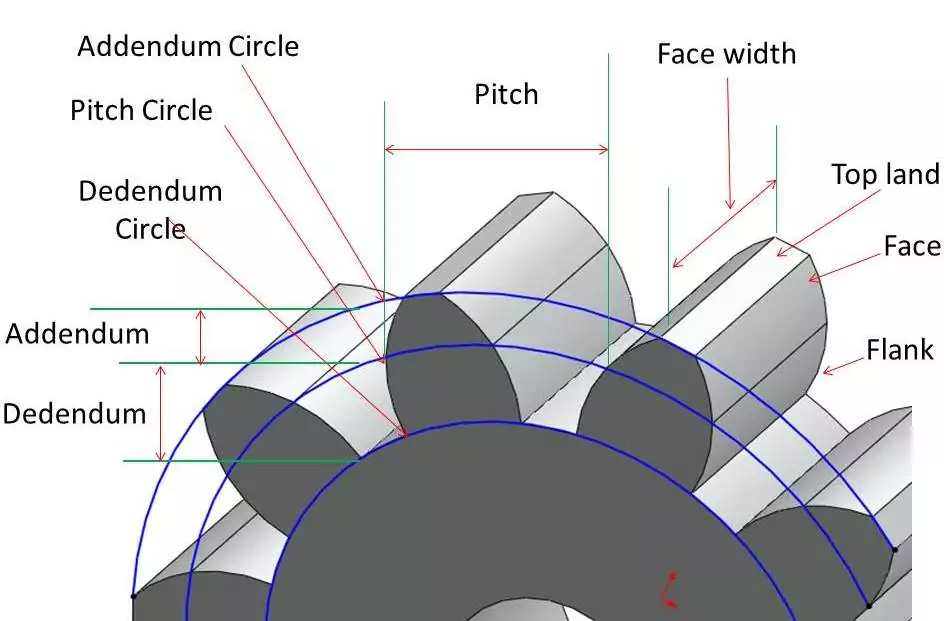

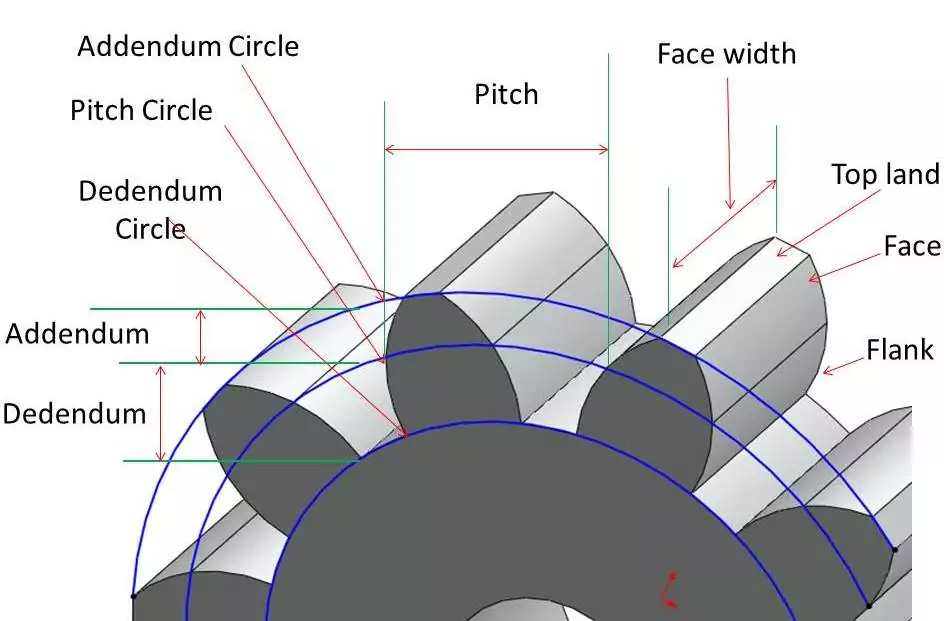

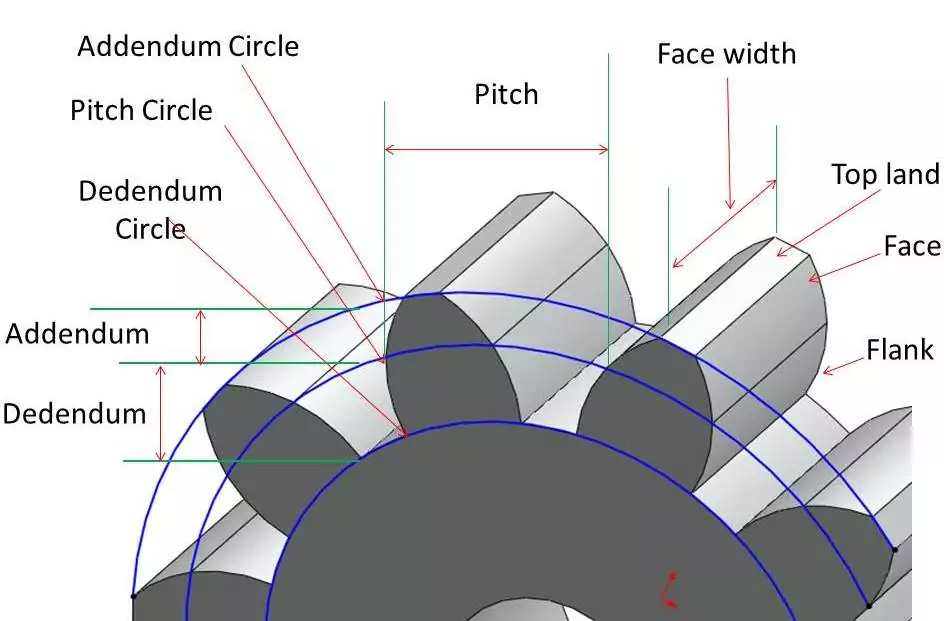

Gears terminology refers to the specialized vocabulary used to describe various aspects of gears, which are mechanical components used to transmit motion and power between rotating shafts. Gears play a crucial role in many machines and mechanical systems.

Gears

Gears are toothed wheels used for transmitting motion and power from one shaft to another when they are not too for apart and when a constant velocity ratio is desired.

A mechanical component with teeth that mesh with the teeth of another gear, transmitting rotational motion and power.

Pitch

The circle from which the gear teeth are geometrically derived. It is an imaginary circle that represents the effective size of the gear.

Pitch of two meshing gear is same. It is define as follow

1.Circular Pitch (p)

It is the distance measured along the circumference of the pitch circle on one tooth to the corresponding point on the adjacent tooth.

2. Diametral Pitch (P)

It is the number of teeth per unit length of the pitch circle dia. in inches.

Module (Metric)

It is the ratio of pitch dia. in mm to the number of teeth.The term is used in S.I. units in place of diametral pitch.

m = d/T

Module is the ratio of the pitch diameter to the number of teeth for metric gears. Diametral pitch is the number of teeth per inch of the pitch diameter for imperial gears.

What is Gear Terminology – Definition of gears

Gear Ratio

It is the ratio of the number of teeth on the gear to that on the pinion.

G = T/t

Where T = Number of teeth on the gear

t = Number on teeth on the pinion

The ratio of the number of teeth on one gear to the number of teeth on another gear in a meshing pair. It determines the speed and torque relationship between the gears.

Addendum

It is the radial height of a tooth above the pitch circle.

An addendum is a term commonly used in gear terminology, particularly in the context of gears and gear design. It refers to the radial distance between the pitch circle (the theoretical circle upon which the gear teeth are spaced) and the top of a gear tooth. In simple terms, it is the height of the gear tooth above the pitch circle.

The addendum is a crucial parameter in gear design because it determines how much a gear tooth extends beyond the pitch circle. It plays a significant role in ensuring proper meshing and engagement between gears, as well as influencing the overall geometry and performance of the gear system.

Dedendum

The dedendum is a term used in the design and analysis of gears, which are mechanical devices that transmit power and motion between rotating shafts.

It is the radial distance from the pitch circle to the bottom of the tooth. In simpler terms, It is the radial depth of a tooth below the pitch circle. Its standard value is 1.157m.

Clearance

In gear terminology, “clearance” refers to the intentional space or gap between two mating gear teeth. This space is crucial for proper gear functioning and prevents interference between the gear teeth.

It’s radial difference between the addendum and the dedendum of a tooth.

Backlash

The clearance or play between meshing gear teeth. It is important to minimize backlash for accurate motion transmission.

It is the difference between the space width and the tooth thickness along the pitch circle.

Backlash is essentially the amount by which a tooth space exceeds the thickness of the engaging tooth on the mating gear. Backlash is important because it can affect the precision and accuracy of gear systems.

When there is backlash between gears, it means that there is some degree of movement or rotation that can occur before the teeth of one gear engage with the teeth of the mating gear. This clearance allows for smooth operation and prevents binding, but excessive backlash can lead to issues such as reduced accuracy, positioning errors, and decreased efficiency in a mechanical system.

Working Depth

It is the distance between top of addendum circle to the clearance circle.

Whole Depth

It is the total depth of a tooth space.

What is Gear Terminology | Definition of gears

Tooth Thickness

The tooth thickness is measured at the pitch diameter.

Tooth thickness is a critical parameter in gear terminology and is an essential factor in the design and analysis of gears. It refers to the width of the gear tooth measured along the pitch circle. The pitch circle is an imaginary circle on a gear that represents the effective diameter where the gear teeth engage each other.

Face Width

It is the distance of top of the gear teeth.

The portion of the tooth profile above the pitch surface is known as the face.

Tooth face

The mating surface of a gear tooth between the addendum circle and the pitch circle.

Tooth Flank

The mating surface of a gear tooth measured between the pitch circle and the base circle.

The portion of the tooth profile below the pitch surface is known as flank.

Filter Radius

It is the radius of the fillet curve at the base of the gear tooth.

Top Land

The top land is the surface of the top of the tooth.

Gear Center

A gear center is the center of the pitch circle.

Gear Range

The gear range is difference between the highest and lowest gear ratios.

Helix Angle

Helix angle is the angle between the helical tooth face and an equivalent spur tooth face.

Profile

The curvature contained by the face and flank is known as the profile.

Contact path

It is the path taken by the contact point from the beginning of the confrontation to the end of the confrontation.

POC = approach path + retreat path

Arc of contact (AOC)

It is the path traced by a point on the primitive circle from the beginning of the confrontation to the end of the confrontation.

Velocity Ratio (VR)

VR = 1/GR

Action angle

Angle rotated by gear from the start of engagement to the end of engagement of a pair of teeth.

The angle of action = angle of approach + angle of recess

Contact Ration (CR)

The contact ratio represents the number of pairs of teeth in contact.

CR= AOC/circular step = Action angle/Step angle

What is Gear Terminology – Definition of gears

FAQ’s

What is gear terminology?

Gears terminology refers to defining the essential parts of the gear. These terminologies are defined to have a perfect design of teeth and gears. For example, some gear terminologies are:

Dedendum

The Tooth’s flank

Primitive circle

appendix circle

fillet radius

circle diameter

Dedendum Circle

Authorization

What is DP in spur gear terminology?

The diametral pitch is abbreviated as DP. Diametral pitch (DP) refers to the number of teeth per inch of pitch circle diameter. Reverse inches (1/in) are the units of DP.

Gear ratio according to gearing terminology?

The gear ratio helps estimate how many teeth each gear has to achieve the required output speed/angular velocity or torque. When only the diameters or radii of the gears are examined, we can derive the gear ratio using the following equation:

gear ratio = (input gear diameter)/(output gear diameter)

You may also like