Table of Contents

Axle

An axle on your vehicle is a rod or axle that turns the wheels and supports the weight of the car. Car and Driver explains that axles are essential components of any vehicle. Since axles conduct the power that turns the wheels, all vehicles need axles to function properly.

An axle is a central shaft that rotates and supports the wheels or rotating parts of a vehicle, such as a car, truck, or bicycle. It plays a crucial role in the transmission of power from the engine to the wheels, allowing the wheels to rotate and the vehicle to move.

In most vehicles, there are two axles: a front axle and a rear axle. The front axle is responsible for steering the vehicle, while the rear axle is primarily responsible for driving the vehicle forward. In some cases, especially in trucks and larger vehicles, there may be multiple axles.

Axles can be solid or split, and they are often connected to the wheels through various components such as hubs, bearings, and differentials. The design and configuration of axles can vary depending on the type of vehicle and its intended use.

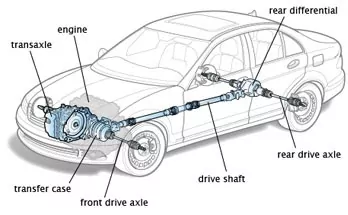

Working of Axle in a Car

An axle is a central shaft for a rotating wheel or gear. In the context of a car, axles play a crucial role in the vehicle’s operation and are responsible for transmitting power from the engine to the wheels, as well as supporting the weight of the vehicle.

There are two main types of axles in a car :- the front axle and the rear axle.

Front Axle

In most cars, the front axle is responsible for both steering and driving the vehicle.

The front axle connects the front wheels and typically includes components such as the axle shafts, constant velocity (CV) joints, and the differential.

The differential is a device that allows the front wheels to rotate at different speeds during turns, compensating for the difference in distance traveled by the inner and outer wheels.

Rear Axle

The rear axle is primarily responsible for supporting the weight of the vehicle and transmitting power to the rear wheels.

The rear axle consists of the axle shafts, differential, and in some cases, a rear axle housing.

The differential in the rear axle performs a similar function to the front axle differential, allowing the rear wheels to rotate at different speeds during turns.

Axle Shafts

Axle shafts are the rods or bars that connect the differential to the wheels. They transmit torque from the differential to the wheels, causing them to rotate.

In modern vehicles, constant velocity (CV) joints are often used on the axle shafts to allow for flexibility and smooth rotation during steering and suspension movement.

Differential

The differential is a crucial component in both the front and rear axles. It allows the wheels on an axle to rotate at different speeds when turning.

In a simple term, the differential compensates for the fact that the inner wheel travels a shorter distance than the outer wheel during a turn.

Axle Housing

Some rear axles have an axle housing, which is a protective casing that houses the differential and axle shafts. It helps support the weight of the vehicle and provides protection for the internal components.

Axles in a car are essential for transmitting power from the engine to the wheels and for supporting the vehicle’s weight. They play a critical role in the overall functionality and performance of a vehicle, and their design may vary depending on whether they are located at the front or rear of the vehicle.

What Are the Parts of an Axle?

An axle is a central shaft around which rotating elements, such as wheels, revolve. Depending on whether it is a front axle or a rear axle, the specific components may vary.

Main parts commonly associated with an axle:

Axle Shaft

The axle shaft is a rod or spindle that connects the wheel to the differential. It transmits torque from the differential to the wheel, causing the wheel to rotate.

Constant Velocity (CV) Joints

CV joints are commonly used on axle shafts, especially in front-wheel-drive and independent suspension systems. They allow for flexibility and smooth rotation of the axle shafts during steering and suspension movement.

Differential

The differential is a device that splits torque between the two wheels connected to the axle. It allows the wheels to rotate at different speeds when the vehicle is turning.

Axle Housing

Some rear axles have an axle housing, which is a protective casing that encloses the differential and axle shafts. The axle housing provides support for the axle components and protection against debris and contaminants.

Wheel Bearings

Wheel bearings are located at the ends of the axle shaft and support the wheel’s rotation. They reduce friction between the axle and the wheel, allowing for smooth and efficient rotation.

Axle Nut

The axle nut is a large nut that secures the axle shaft to the hub of the wheel. It is typically tightened to a specific torque to ensure proper function and safety.

Hub

The hub is the central part of the wheel assembly to which the axle is connected. It contains the wheel bearings and provides a mounting surface for the wheel.

Splines

Splines are ridges or grooves on the axle shaft that match corresponding features in the wheel hub or other connected components. They ensure a secure connection and allow torque to be transmitted.

Retaining Hardware

Various nuts, bolts, and clips are used to secure components together. These may include retaining clips for CV joints, bolts for securing the axle housing, and other fasteners.

The specific design and arrangement of these parts may vary depending on the type of axle (front or rear), the vehicle’s make and model, and the suspension system employed (e.g., solid axle or independent suspension). Regular maintenance and inspection of these components are essential for ensuring the safe and efficient operation of the axle.

How Many Axles Does a Car Have?

The number of axles a car has depends on its configuration and design. In general, passenger cars typically have two axles, with each axle supporting two wheels. Therefore, most cars are considered to be two-axle vehicles.

Here’s a breakdown of the axles in a typical car:

Front Axle

The front axle is responsible for steering and is connected to the front wheels. In many cars, especially those with front-wheel drive, the front axle is also responsible for driving the vehicle.

Rear Axle

The rear axle is located at the back of the vehicle and is responsible for supporting the weight of the car and transmitting power to the rear wheels. In rear-wheel-drive vehicles, the rear axle is the driving axle.

A standard passenger car has two axles: a front axle and a rear axle. Each axle is associated with a pair of wheels, bringing the total number of wheels on a car to four. However, it’s worth noting that some vehicles, such as trucks, buses, and larger SUVs, may have more than two axles. Trucks, for example, may have additional axles to support heavier loads and improve stability.

Type of Axle

- Rear Axle

- Front Axle

- Stub Axle

1. Rear Axle

The rear axle assembly supports 50% to 80% of the vehicle weight and also driving the rear wheels at the same time.

The rear axle assembly can be divided into the two half axle shaft that drives the wheels through a differential gear usually through a spline connection. floating axle

A housing completely enclose the short axle shaft and gear thereby protect them from dust, damage and water.

Rear axle housing is mounted on the leaf spring to prevent the vehicle from road vibration.

The live rear axle half shaft have to withstand the following loads

1) Shearing force due to weight of body.

2) Side thrust caused by side forces during turning.

3) Bending moment due to offset between the spring seat and road wheel.

4) Bending moment caused due to side forces and reaction by the tyres on the ground.

5) Driving torque transmitted to road wheel.

Type of Real Axle

The rear axle are classified as per the mounting of bearing in the axle housing.

a) Semi-floating type

In this type bearings are installed in between the axle housing and the axle shaft and wheel is fitted directly to the flanged at outer end of shaft by bolts, while inner enf of the axle shaft is splines to the differential side gear.

It has to support all the load as side thrust and driving torque.

The vehicle load is transmitted to the axle through the casing and bearing which causes bending and shearing of the axle. It is simplest and cheapest than other type of axle and widely used in cars.

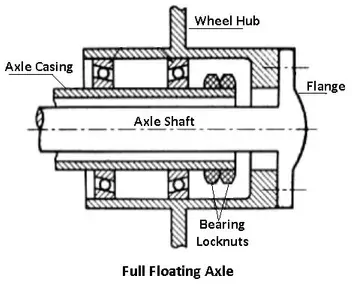

b) Full floating type

This type of axle two taper roller bearing are used. Bearing are placed between the axle housing and the wheel hub. Since the load of the vehicle is supported completely by the axle housing.

The axle only transmit driving torque. The inner end of the axle is supported in side gear of differential and outer end have a flange to which wheel hub is bolted.

Axle mey be removed or replaced from the housing without disturbing the wheel by removing the nut. This type of axle is more expensive and heavier than other axle. This tyep of axle is used in trucks or commercial vehicles.

c) Three quarter floating type

A single bearing is installed between the axle housing and the wheel hub and the wheel is fitted directly to the shaft.

Thus, the weight of the vehicle is transferred to the axle casing and only side thrust and driving torque are taken by the axle.

The axle is keyed rigidly to the hub, thus provide the driving connection and maintaining the alignment of the wheel. It is more reliable and robust one.

Different Stresses to be Resisted by Rear Axle

1) Shear force due to weight of body

2) Side thrust causal by side forces during tearing

3) Bending Moment due to offset between spring seat and road wheel.

4) Bending Moment due to side forces and reaction by the tyre on the groond.

5) Driving torque transmitted to road wheel.

2. Front Axle

The front axle is rigid axle called as dead axle. The front axle transmit the weight of front part of the vehicle to the road surface through the front wheels.It also caries the steering mechanism and absorbs shock due to road variation.

They are straight axle, double drop axle and fully drop axle. These are made by drop forging from steel having 0.4% carbon or 1.3% nickel steel.

The front axle is made of I section at the centre portion. While the ends are made either circular or elliptical. The I section construction takes bending loads due to the load of the vehicle and also the torque due to braking of the wheels.

To keep the chassis height low the centre portion of the front axle is given a downward sweep.

The rigid type front axle was used in connection with leaf springs. Two longitudinal leaf spring fixed to the two spring seat on the axle beam.

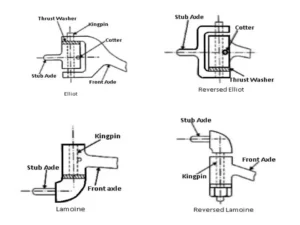

3. Stub Axle

The main front axle beam is connected to wheel spindle by mean of king pin or spindle bolt. The front wheels are mounted on the stud axle.The different four types of stub axle shown in below fig.

Reverse Elliot type is most common stud axle are made of 3% nickel steel and alloy steel containing chromium and molybolenum. This type of streering head, the steering knuckle is forked and the axle proper fit inside the fork.

In Elliot type, the steering knuckle is inserted between the forked end of the axle.

In the Lamoine type of steering head, the L shape steering knuckle is attached with the axle end by a pivot. It is used in tractors.

The reverse elliote type is most popular because

1) It is easier to manufacture.

2) Load exerted by the stub axle is equally distributed.

3) It is more adaptable for use with front brake and also allow a simpler steering arrangement.

Application

A) In many heavy duty truck like Ashok leyland, Eicher, TATA etc.

B) Light duty vehicle like Metadoor etc.

Difference between Rear Axle and Front Axle

| Rear axle | Front axle |

| Rear axle is a rotary axle transmit power or motion to the wheel. | Front axle is a rigid axle transmit the weight of vehicle part to road surface. |

| It takes bending movement, torque reaction and driving thrust reaction and weight of body. | It take only weight of body. |

| This is not directly fixed to suspension system but through axle housing. | Directly fixed to suspension system depending upon type of drive. |

| For power transmission it brake into two half axle shaft. | It is a complete a straight axle. |

Why Is the Axle’s Strength Important?

The strength of an axle is crucial for several reasons, primarily related to the safety, performance, and durability of a vehicle.

Some key reasons why axle strength is important

Load-Bearing Capacity:

Axles support the weight of the vehicle and its occupants. The axle must be strong enough to handle the static weight of the vehicle as well as dynamic loads, such as those experienced during acceleration, braking, and cornering. Insufficient axle strength could lead to structural failure, compromising the vehicle’s safety.

Torque Transmission:

Axles transmit torque from the engine to the wheels, propelling the vehicle forward or backward. The axle must be able to withstand the twisting forces generated by the engine’s power. In high-performance or heavy-duty applications, such as trucks or off-road vehicles, the axle must be even stronger to handle increased torque loads.

Durability and Fatigue Resistance:

Axles are subjected to repetitive loading and unloading cycles, which can lead to fatigue failure over time. A strong axle is more resistant to fatigue, ensuring a longer lifespan and reducing the likelihood of unexpected failures.

Off-Road Performance:

In off-road vehicles, such as trucks and SUVs used for off-roading or recreational activities, the axle is exposed to additional stresses and impacts. A robust axle is essential for handling rough terrain, uneven surfaces, and obstacles without sustaining damage.

Towing and Payload Capacity

Vehicles designed for towing or carrying heavy loads, such as trucks and SUVs, require axles with higher strength to handle the increased weight and stress associated with towing trailers or carrying heavy cargo.

Safety:

The integrity of the axle is critical for overall vehicle safety. A failure in the axle can lead to a loss of control, accidents, or other hazardous situations. Ensuring that axles are designed and manufactured to meet safety standards is essential for protecting occupants and other road users.

Performance and Handling:

The strength of the axle contributes to the vehicle’s overall performance and handling characteristics. A strong axle helps maintain stability during acceleration, braking, and cornering, providing a smoother and safer driving experience.

Compliance with Regulations:

Vehicle manufacturers must adhere to safety and performance regulations set by automotive authorities. Axles need to meet or exceed these standards to ensure that vehicles are safe and roadworthy.

The strength of an axle is critical for the safety, reliability, and performance of a vehicle. Manufacturers carefully engineer and design axles to withstand the various forces and stresses they encounter during normal operation, ensuring that vehicles operate safely and efficiently over their lifespan.

Factors That Decide the Type of Axle in a Car

Several factors influence the type of axle used in a car. The choice of axle type is often determined by various design considerations, intended use of the vehicle, and engineering priorities.

Some key factors that influence the selection of the type of axle in a car

Drive Configuration

The location of the engine and how power is transmitted to the wheels play a significant role. Front-wheel-drive (FWD) cars typically have a front axle responsible for both steering and driving, while rear-wheel-drive (RWD) cars have a rear axle for driving. All-wheel-drive (AWD) or four-wheel-drive (4WD) cars may have both front and rear axles involved in driving.

Suspension Design

The type of suspension system used in a vehicle can influence the axle configuration. Independent suspension systems may require different axle designs compared to solid axle (beam axle) systems.

Vehicle Type

The type of vehicle, whether it’s a passenger car, SUV, truck, or performance vehicle, can influence the choice of axles. Trucks and SUVs designed for heavy towing or off-road use may have different axle requirements compared to standard passenger cars.

Performance Requirements

High-performance vehicles often have specific axle requirements to handle increased power and torque. Performance cars may have reinforced axles, limited-slip differentials, or other features to enhance handling and traction.

Weight Distribution

The distribution of weight between the front and rear of the vehicle affects the axle design. Front-heavy or rear-heavy vehicles may require different axle configurations to ensure optimal weight distribution and balance.

Cost Considerations

The cost of manufacturing and installing different types of axles can influence the decision. Manufacturers aim to balance performance and safety with cost-effectiveness.

Fuel Efficiency

The choice of axle can impact fuel efficiency. For example, front-wheel-drive configurations are generally more fuel-efficient due to the reduced weight and mechanical losses compared to rear-wheel-drive configurations.

Off-Road Capability

Vehicles designed for off-road use, such as SUVs and trucks, may require specific axle features like increased ground clearance, reinforced components, and differential locks to handle rough terrain.

Regulatory Compliance

Vehicles must comply with safety and emission regulations, and the choice of axle may be influenced by the need to meet these standards.

Manufacturer’s Design Philosophy

Each automaker may have its own design philosophy and preferences when it comes to axle configurations. Some manufacturers may favor certain axle types for specific vehicle models or classes.

Market Demand and Trends

Consumer preferences and market trends can also influence the choice of axle configurations. For example, the popularity of SUVs and crossovers has led to an increase in the adoption of front-wheel-drive and all-wheel-drive configurations.

The type of axle in a car is determined by a combination of engineering considerations, performance requirements, vehicle design, and market demands. Manufacturers carefully evaluate these factors to select the axle configuration that best meets the needs of the vehicle and its intended use.

What are the common issues with car axles?

Car axles are robust components, but they can experience various issues over time due to factors such as wear and tear, poor maintenance, or external damage.

Some common issues associated with car axles:

CV Joint Failure:

Constant Velocity (CV) joints are critical components in front-wheel-drive and some all-wheel-drive vehicles. These joints allow the axle shaft to flex and rotate during steering and suspension movements. CV joint failure can lead to clicking or popping sounds during turns.

Boot Damage:

CV joints are protected by rubber boots that contain lubricating grease. If these boots become damaged or torn, dirt and contaminants can enter, leading to premature wear of the CV joint and potential failure. Regular inspection of CV joint boots is important.

Leaking Differential Fluid:

Rear axles, especially those with differentials, may develop leaks in the seals or gaskets, leading to a loss of differential fluid. Low fluid levels can result in poor lubrication, increased friction, and potential damage to the differential components.

Bearing Failure:

Wheel bearings, which support the rotation of the wheels on the axle, can wear out over time. Failed wheel bearings often produce a humming or grinding noise. If not addressed, it can lead to uneven tire wear and compromised handling.

Axle Shaft Damage:

Axle shafts can bend or suffer damage due to collisions, potholes, or other impacts. A damaged axle shaft can result in vibrations, noise, or difficulty driving the vehicle.

Differential Noise:

Noises coming from the differential, such as whining or clunking sounds, may indicate issues with the gears, bearings, or other internal components. Differential problems can affect the vehicle’s performance and should be addressed promptly.

Excessive Vibration:

Imbalances in the axle assembly, bent axle shafts, or worn-out universal joints can lead to vibrations during acceleration or at certain speeds. Excessive vibration may indicate a problem with the axles or related components.

Lack of Lubrication:

Insufficient lubrication in the axle and differential can lead to increased friction, heat, and wear. Regular maintenance, including checking and changing differential fluid, is crucial to prevent such issues.

Torn Sway Bar Links:

Sway bar links connect the axle to the vehicle’s chassis and help stabilize the suspension. Torn or damaged sway bar links can lead to handling issues, uneven tire wear, and clunking noises.

Axle Seal Leaks:

Seals are used to prevent fluid leakage from the axle assembly. If these seals fail, it can lead to leaks of lubricating oil. This can result in decreased lubrication and potential damage to internal components.

Worn U-Joints:

Universal joints (U-joints) in the drive shaft can wear out over time, leading to vibrations, clunking noises, or drivetrain issues. Regular inspection and replacement of worn U-joints are important for maintaining driveline integrity.

How to Measure Axle Length

Measuring the length of an axle can be a straightforward process if you have access to the axle and some basic measuring tools.

General guide on how to measure the length of an axle:

Tools Needed:

Measuring Tape or Ruler:

A measuring tape or ruler with clear markings in inches or millimeters.

Calipers (optional):

Calipers can be useful for measuring small or precise dimensions.

Steps:

Identify the Axle:

Make sure you are measuring the correct axle. If the vehicle is raised, safely support it with jack stands, and locate the axle you want to measure.

Choose the Starting Point:

Determine the starting point for your measurement. The axle length is typically measured from end to end, including any protruding ends or mounting surfaces.

Position the Measuring Tool:

If you’re using a measuring tape, place the end of the tape at one end of the axle. If you’re using a ruler or calipers, position the measuring tool along the axle.

Extend the Measuring Tool:

Extend the measuring tape or ruler along the axle until you reach the other end. Ensure that you are following the contour of the axle and measuring the full length.

Record the Measurement:

Read the measurement at the point where the measuring tool ends. Note the measurement in inches or millimeters.

Measure Twice for Accuracy:

For accuracy, it’s a good practice to measure the axle length at least twice to confirm your measurement. This helps reduce the risk of errors.

Tips:

Include Mounting Surfaces:

If the axle has protruding ends that mount to other components (e.g., hub, differential), include these mounting surfaces in your measurement.

Measure Straight Sections:

If the axle has straight sections between mounting surfaces, measure along these sections for a more accurate measurement.

Consider Tapered Axles:

Some axles may have tapered ends. In such cases, measure from the widest point of the taper.

Note Vehicle Specifications:

If you’re working on a specific vehicle, check the vehicle’s specifications or service manual for axle length information. This can serve as a reference to ensure your measurement aligns with the manufacturer’s specifications.

Consult a Professional:

If you’re unsure or if the axle is in a complex assembly, consider consulting a professional mechanic for assistance. They may have specialized tools and knowledge to accurately measure the axle.

Always prioritize safety when working on or around vehicles. If you are uncertain about any aspect of the measurement process or if the axle is part of a complex assembly, seek professional assistance to ensure accuracy and safety.

Drive Shaft vs. Axle Shaft

The terms “drive shaft” and “axle shaft” refer to different components of a vehicle’s drivetrain, and they serve distinct purposes.

Drive Shaft

The drive shaft, also known as a propeller shaft, is a mechanical component that transfers torque and rotation from the vehicle’s transmission to the differential, which then delivers power to the wheels. It is a rotating shaft that spans the distance between the transmission output shaft and the input shaft of the differential. The drive shaft is a crucial part of rear-wheel-drive and some four-wheel-drive vehicles.

Key Characteristics:

Connects the transmission to the differential.

Typically a single, long shaft.

Can have universal joints (U-joints) to allow for flexibility and accommodate variations in angles between the transmission and differential.

Function:

Transfers torque from the engine to the differential, allowing the wheels to be powered.

Axle Shaft

Axle shafts are the shafts or rods that connect the differential to the wheels of a vehicle. They transmit torque from the differential to the wheels, causing the wheels to rotate. Axle shafts are part of the axle assembly, which includes the differential, axle shafts, and other components. In front-wheel-drive vehicles, the front axle shafts are responsible for both steering and driving the front wheels.

Key Characteristics:

Connects the differential to the wheels.

There are front axle shafts and rear axle shafts, depending on the location in the vehicle.

Can have constant velocity (CV) joints to allow for flexibility during steering and suspension movements.

Function:

Transmits torque from the differential to the wheels.

In rear-wheel-drive vehicles, rear axle shafts are responsible for driving the rear wheels.

The drive shaft is responsible for transferring torque from the transmission to the differential, while axle shafts transmit torque from the differential to the wheels. Both components play essential roles in the overall functionality of a vehicle’s drivetrain. The specific design and configuration may vary depending on the vehicle’s layout, whether it’s front-wheel-drive, rear-wheel-drive, or four-wheel-drive.

Advantages And Disadvantages of Axle

Axles are crucial components in various vehicles and machinery, serving as shafts around which wheels rotate. There are different types of axles, such as live axles and dead axles, each with its own set of advantages and disadvantages.

Advantages of Axles

Support and Rotation:

Advantage: Axles provide support for the weight of the vehicle or machinery and facilitate the rotation of the wheels.

Weight Distribution:

Advantage: Axles help distribute the weight of the vehicle evenly across the wheels, contributing to stability and balance.

Simplicity:

Advantage: Axle systems are relatively simple in design, making them cost-effective to manufacture and maintain.

Durability:

Advantage: Axles are typically robust and durable, capable of withstanding heavy loads and rough terrains.

Traction:

Advantage: Axles contribute to traction by ensuring that the power from the engine is effectively transferred to the wheels.

Disadvantages of Axles

Limited Independent Suspension:

Disadvantage: Some axle configurations, like live axles, may limit independent suspension, resulting in a rougher ride, especially on uneven surfaces.

Weight:

Disadvantage: Axles themselves add weight to the vehicle, which can affect fuel efficiency and overall performance.

Complexity in Steering:

Disadvantage: In certain designs, especially those with rigid axles, steering can be less responsive compared to vehicles with independent suspension systems.

Turning Radius:

Disadvantage: Vehicles with axles may have a larger turning radius compared to those with more advanced suspension systems, affecting maneuverability in tight spaces.

Maintenance Challenges:

Disadvantage: While axles are generally durable, they may require more maintenance in certain situations, especially in off-road conditions or when subjected to heavy loads.

Uneven Tire Wear:

Disadvantage: Axles, particularly in live axle configurations, can lead to uneven tire wear, impacting the longevity of tires.

Limited Articulation:

Disadvantage: Some axle designs, especially in off-road vehicles, may have limited articulation, affecting their ability to navigate challenging terrains.

The advantages and disadvantages of axles can vary based on the specific application, vehicle type, and intended use. Engineers often choose axle configurations based on the requirements and constraints of the vehicle or machinery in question.

FAQ’s

What are axles in a car?

An axle is a rod or axle that connects a pair of wheels to drive them and maintain the position of the wheels relative to each other. In a car, the engine applies force to the axle that turns the wheels and moves the vehicle forward. In other words, the axles transmit the engine’s driving power to the wheels.

How many axles does a car have?

In most cases, cars have two axles to turn the wheels. Larger vehicles that carry more passengers and have more wheels may have more axles. It is easy to identify the number of axles your car or any other vehicle has. Simply look at your car from the side and then count the pairs of tires.

What is the axis formula?

In the case of the wheel and axle, the mechanical advantage can be calculated simply by comparing the radius of the wheel to the radius of the axle, using the formula

Ma=Rw/Ra.

In this formula, Ma represents the mechanical advantage, Rw represents the wheel radius, and Ra represents the axle radius.

You may also like

How clutch work inside car with animation