Table of Contents

Cluth and Necessity for a clutchs

Clutch is a device used to transmission system of a vehicle to transmite the rotary motion of one shaft when desired to second shaft of which axis are coincident with that of first. Thus, the clutch is located between the engine and the transmission system.

When the clutch is engaged, power transmit from the engine to the driving wheels through the transmission system and the vehical moves.

When the clutch is disengaged, the power is not transmitted to the driving wheel and the vehile stop, while the engine is still running.

In a vehicle, the clutch is always in the engaged position. The clutch is disengaged during the gear shifting, while stopping the vehicle or during breaking and when idling the engine. It should be disengage by operating the clutch pedal.

When clutch operated properly it prevents sudden jerk motion of the vehicle and this avoids putting under strain on the remaining part of the power transmission.

Why Clutchs Require

1) It should be able to transmit maximum torque of the engine.

2) It should be engage gradually to avoid sudden jerk.

3) It should be able to dissipate large amount of heat generated during clutch operation.

4) It should be dynamically balance, for high speed engine.

5) It should have suitable mechanism for damp vibration and reduce noise during power transmission.

Working principle

A clutch is a mechanism used to transmit the rotating motion of one shaft to another when desired and the axis of both the shaft are coincident.

It works on the principle of friction. It connect the engine shaft and gear box shaft. The transmission of power can be affected by friction between two or more, rotating concentric surfaces, called as friction plate.

The friction plates can be pressed firmely against one another by means of axial force provided by spring and the pressure plate.

When it engaged and the clutch tends to rotate as a single unit, the rotating speed of the concentric surface or other shaft is depend upon the friction force which is proportional to axial force applied by spring.

Function

1) To permit engagement or disengagement of a gear when the vehicle is stationary and the engine is running.

2) Transmit the engine power to the road wheel smoothly without shocks to the transmission system while setting the vehicle in motion.

3) To permit the engaging of the gear when the vehicle is in motion without damping the gear wheel.

What Are the Parts of a Clutch?

A clutch is a mechanical device that engages and disengages the power transmission between the engine and the transmission system of a vehicle. It is a crucial component in manual transmission systems, allowing the driver to control the power flow.

The main parts of a clutch include

Clutch Disc (Friction Disc): This is a flat, circular plate lined with friction material on both sides. It is located between the flywheel and the pressure plate. When the clutch is engaged, the clutch disc is pressed against the flywheel, allowing power to be transmitted from the engine to the transmission.

Flywheel

The flywheel is a heavy, rotating disc connected to the engine’s crankshaft. It provides inertia and a smooth surface for the clutch disc to engage with. The flywheel also helps to maintain a consistent speed and balance in the engine.

Pressure Plate

The pressure plate is a metal plate that is bolted to the flywheel. It applies pressure to the clutch disc through a set of springs or a diaphragm spring when the clutch is engaged. This pressure allows the clutch disc to grip the flywheel, enabling power transmission.

Release Bearing (Throw-out Bearing)

This bearing is mounted on the clutch fork and is responsible for engaging and disengaging the pressure plate. When the driver presses the clutch pedal, the release bearing moves towards the pressure plate, releasing the pressure on the clutch disc and allowing it to disengage from the flywheel.

Clutch Fork

The clutch fork is a lever that pivots on a fulcrum and is connected to the release bearing. When the clutch pedal is depressed, the clutch fork moves, pushing the release bearing against the pressure plate, which releases the pressure on the clutch disc.

Clutch Pedal and Linkage

The clutch pedal is located inside the vehicle and is connected to the clutch linkage. When the driver presses the clutch pedal, it activates the clutch linkage, which in turn engages or disengages the clutch by moving the clutch fork.

Clutch Housing

The clutch housing encases the entire clutch assembly and connects it to the transmission system. It provides protection and support for the clutch components.

When the clutch pedal is depressed, the clutch disengages, allowing the driver to shift gears or come to a stop without turning off the engine. When the clutch pedal is released, the clutch engages, connecting the engine to the transmission, and enabling power to be transferred to the wheels.

Types of Clutches

Single Plate Clutch

Multiplate Clutch

Diaphragm Clutch

Semi Centrifugal Clutch

Centrifugal Clutch

Cone Clutch

Single Plate Clutch

Construction and Working

It cnsist of flywheel, pressure plate, clutch plate with friction lining/faces called fricton plate, clutch pedal, thrust and ball bearing and clutch springs.

It has only one clutch plate, mounted on the hub which is spline internally and free to slides over the clutch shafts.

Flywheel is mounted on the crankshaft and rotate with it.

The pressure plate is fixed to the flywheel through clutch spring by means of bolts.

The springs are arranged circumferentially to provide axial force on pressure plate to keep the clutch in engage position .

The friction plate held between flywheel and pressure plate having friction facing on both side to provide two annular friction surface for power transmission.

When clutch pedal is pressed the pressure plate is moved to the right against the spring force and this is achieved by means of suitable linkage and thrust bearing.

Due to this movement of the pressure plate, the friction plate is released and clutch is disengaged and when pedal is released the pressure plate moves to left due to clutch spring arranged circumferentially and thus clutch again engaged.

Advantages

Gear changing is easier than the cone clutch because the pedal movement is less.

It is more reliable because it does not suffer from disadvantage of binding of cone.

Disadvantage

The springs have to be more stiff hence greater force required by the driver for disengaged.

Application

This clutch is used in four wheeler like Truck, Jeep, Fiat-1100, Tata sierra etc.

Multiplate Clutch

Construction and Working

It is a modification of single plate type where increase the number of friction plate ( friction surface and clutch plate).

Due to this friction surface increasing, the torque transmission capacity of clutch increased, the size remaining fixed, Alternatively the size of the clutch is reduced for same power transmission as a single plate clutch.

This type of clutch is used in heavy transport vehicles and racing cars where high torque transmitted.

This clutch is also used in scooter and motor cycle as space available is limited.

It consits of flywheel, pressure plate, spigot end with clutch spring, thrust bearing and clutch pedaland two sets of friction plate.

One set of friction plate slides in longitudinal groove of flywheel and other one slides on splines on the pressure plate hub.

The friction plates are arranged alternatively to each set.

When the clutch pedal is pressed, the axial pressure acts on the pressure plate to move right and compressing the clutch spring at the spigot end.

Thus pressure on friction plate released and it is disengaged.

When clutch pedal released the clutch spring exert a pressure on the pressure plate to moves the pressure plate to left and thus clutch again engaged.

Advantages of the multi-Plate clutch

Decrease clutch weight.

It has a very compact size.

Increase the amount of torque you transmit.

Decrease the moment of inertia of the clutch.

Disadvantages of the multi-plate clutch

They heat up quickly.

Multi-disc clutches are heavy.

Multi-disc clutches are too expensive.

Multi-Plate clutchs application

Multi-disc clutches are used where compact construction is required, for example scooters, motorcycles and racing cars.

The multi-plate clutch is used in some heavy commercial vehicles to transmit high torque.

Diaphragm Clutch

Construction and Working

In this clutch, in order to produce the required pressure for engaging it, a form of diaphragm or conical spring is employed in place of coil spring.

This type of clutch is quite advantageous because it requires no release levers and the spring itself acts as a series of levers.

Some of the conical springs used even are not having the constant-rate characteristics.

The pressure of spring is always varying.

It increases till the spring reaches to its flat position and decreases with the passing of this position.

In case of this clutch, the driver has not to exert as high a pedal pressure to hold the clutch out of engagement as in case of a coil spring type.

In case of a coil spring type of clutch, when the pedal is depressed to disengage the clutch, the spring pressure further increases.

The spring is pivoting on the rear pivot rings in its engaged position while holding itself on the clutch cover.

In this position the pressure plate is in contact with its outer rim. Therefore, sufficient pressure is exerted by the spring making a firm contact between the pressure plate and clutch plate as well as the flywheel in this natural conical position.

Now in order to disengage the clutch, the pedal is depressed.

The throughout bearing is moved toward the flywheel by the linkage due to pedal depression.

As the spring is pivoting on the front pivot ring, therefore, the bearing contacting the inner portion of the conical spring moves that portion forward resulting the rim to move backward.

The clutch disc gets released from the contact with both the driving members because the pressure on the pressure plate is removed.

The release levers would move towards the withdrawn bearing and prevent the clutch from engaging fully due to wearing down of the friction lining.

To prevent the clutch slipping , a free movement of about 25 mm at the clutch pedal or 1.5 mm at the withdrawal bearing is provided.

Diaphragm Clutch Advantages

It is lighter in weight.

It has compact size.

The diaphragm spring applies more force, therefore it has a higher torque transmission capacity.

It has fewer rotating parts, therefore no noisy working problem.

It has dynamic roll even at high speed.

Diaphragm Clutch Disadvantages

For heavy vehicles, the size of the clutch increases to increase the friction surfaces.

The diaphragm clutch has the following applications

maruri suzuki swift

tata storm safari

Ford Eco Sport

Semi Centrifugal Clutch

Construction and Working

In this type of clutch light clutch spring of sufficient strength exerting low pressure at idling speeds are used.

Also the pressure between the friction plate is increased with the increase of speed of rotation of the clutch in proportion to the pressure requirements by means of centrifugal weight attached to the hinged lever at qual interval.

The pressure plate moves towards the flywheel and the ends of the release lever are moves back against the throw out bearing by the action of centrifugal force which increase by increase in speed of rotation.

The clutch spring pressure exert low pressure at the idling speed can be used by this set for facilitating the depression of the clutch pedal for shifting gear.

As the speed of rotation increase, the rotating weight tends to move the pressure plate toward the flywheel .

The ends of release levers are also moved back against the throw out bearing along with this movement of the pressure plate.

Advantages

Clutchs operation is very easy.

Less stiff clutch springs are used as they work only at low engine speeds.

Disadvantages

The springs have transmitted torque at lower engine speeds only.

Centrifugal forces work only at higher engine speeds to transmit torque.

Applications

The semi-centrifugal clutch is used in Vauxhall cars.

Centrifugal Clutch

Construction and Working

The centrifugal clutch is extensively used in light two wheelers like moped or two wheeler without gear.

The centrifugal clutch uses centrifugal force, instead of spring force for keeping it in engaged position, it does not require clutch pedal for operating a clutch.

The clutch is operated automatically depend upon the engine speed.

The vehicle can be stop in gear without stalling the engine and driver can started a vehicle selecting any gear.

It consist of flywheel, pressure plate, friction plate, spring, cover with stopper and bell crank lever.

As the accelerator pedal is pressed, the engine speed increases. The weight A attached to one end of bell crank lever flies upward exerting a pressure on pressure plate C through the spring E.

The friction plate D pressed against the flywheel F thereby engaging the clutch.

The spring G serve to keep the clutch disengaged at low speed. H is the stopper for limit the amount of centrifugal force.

Advantages

It is simple and requires less maintenance.

it is cheap

Since it is automatic, so you don’t need the necessary control mechanism.

Its coupling speed can be controlled by selecting an appropriate spring.

Helps prevent engine stalling.

Disadvantages

There is a loss of power in it due to slippage and friction.

It is not capable of transferring a large amount of power and slips under heavy load conditions.

You experience an overheating problem.

Their coupling depends on the speed of the drive shaft.

Centrifugal Clutch Applications

A centrifugal clutch can be useful for a range of engine driven equipment with high starting inertia. They are commonly found in mobile equipment with rotating parts that are powered by small diesel or gasoline engines. Centrifugal clutch is mainly used in lawnmowers, mopeds, go-karts, mini bikes, chainsaws, etc. Some of these examples include

Vibratory plate and roller compactors

rammers

Compressor/vacuum/fan units

Concrete and trowel finishers

Compact Street/Road Cleaners

Transport refrigeration units

mobile water pumps

Garden equipment: rotary and flail mowers, lawnmowers and scarifiers

go kart

Wood chippers/stump grinders/milling machines

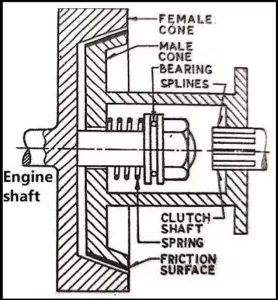

Cone Clutch

Construction and Working

The cone clutch consist of friction surfaces in the shape of cone.

The engine shaft consist of a female cone and male cone is mounted on clutch shaft which is spline and male cone free to slide over clutch shaft.

The male cone is provided with friction surfaces.

When male cone are brought in contact with female cone the clutch is engageddue to force of spring when the clutch pedal is pressed, male cone slides toward right against the spring force by compressing the spring and the clutch is disengaged.

The cone clutch is practically obsolete due to some disadvantages.

If the angle of cone is made smaller than 20 degree, the male cone tends to bind in the female cone and it became difficult to engaged.

Advantages

In this clutch the normal force acting on the contact surfaces is greater than the axial force.

It can transfer high torque compared to same size plate clutches.

Because the contact surfaces are wedge-shaped, less effort is required to engage the clutch.

Creates less noise than other clutch plates.

Disadvantages

If the angle of the cone is large, the effort required to disengage the clutch will be greater.

Even a little wear on the cone surface interrupts the correct operation of the clutch.

If the angle of the cone becomes less than about 20°, the male cone tends to bind or bind with the female cone and it becomes difficult to disengage the clutch.

Cone Clutchs Application

Cone Clutch used in various manual transmissions as synchronizers.

They are used in various heavy machines as they can transmit high torque.

These clutches are generally used in low peripheral speed applications.

Cone clutches are commonly used on power racing boats.

Cone clutches are used in racing and rally vehicles.

FAQ

What is the function of clutch?

The function and purpose of a clutch is to transmit torque from a rotating driving motor to a transmission. Clutches require a mode of actuation in order to break the transmission of torque.

What are the parts of clutch?

The four parts that make up the clutchs are

Clutch Plate.

Cover.

Bearing (Release bearing)

Release Fork (clutch fork)

Where is the clutch located?

The clutch is in the middle of transmission and engine. So that torque can be transmitted from engine to the transmission whenever required.

How is clutch made?

These clutches are usually made up of a stack of alternating friction plates and steel plates. The friction plates have lugs on their outer diameters that lock them into a basket that is turned by the crankshaft. The steel plates have lugs on their inner diameters that lock them to the transmission input shaft.

You may also read