Table of Contents

Hydraulic Hose Pipe

Hydraulic Hose pipe is designed to carry hydraulic fluid in actuators and valves etc. Hoses made with high precision can take high level pressure. The hose has a very wide application in the hydraulic industry.

There are number of applications in the hydraulic system where rigid piping is not suitable..

1) When pipe is to bend for short distance connection.

2) Drive unit is to moved with the pipe line.

Hence, flexible pipes which can be easily bend to any shape are used in hydraulic system. These flexible pipes are known as hydraulic hose pipe.

They are made of composite material in the form of rubber reinforced with fibre or steel wire brading.

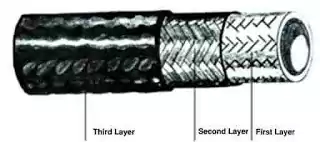

Usually hoses are constructed in three layers

a) Inner tube

It is rubber or other synthetic material tube through which the fluid is passed and it comes directly in contact with the pressurised oil.

b) Re- inforcement

It gives strength to the hose in the form of wire arranged in grid design, it uses steel wire of high tensile strength to withstand very high working pressure, permit longer life, and more durability to the hose.

The steel wire may be either spirally woven or cross-woven.

c) Outer protective layer

The reinforcement of the hose is protected by the outer cover from corrosion, abrasion and other damage.

Various types of synthetic elastomers having excellent abrasion resistance and weather resistance materials are used for outer protective layer.

Neoprene, synthetic GRS rubbers are commonly used for this cover.

Sometimes sleeves are provided for protection of hoses from external rubbing, abrasion etc.

What is Hydraulic Hose Pipe – Factor, Type, Selection criteria, More

Type Of Hydraulic Hose Pipe

Hydraulic hoses are essential components in hydraulic systems, transferring hydraulic fluid under high pressure to drive various machinery and equipment. These hoses are designed to withstand the rigors of hydraulic applications and are constructed with different materials and specifications based on the specific needs of the system.

Here are some common types of hydraulic hoses:

Rubber Hydraulic Hoses:

Low-Pressure Rubber Hoses: Used for applications with lower pressure requirements.

Medium-Pressure Rubber Hoses: Suitable for a wide range of industrial applications with moderate pressure levels.

High-Pressure Rubber Hoses: Designed to handle high-pressure hydraulic systems and often used in heavy-duty applications.

Thermoplastic Hydraulic Hoses:

Low-Pressure Thermoplastic Hoses: Lightweight and flexible hoses suitable for low-pressure hydraulic systems.

High-Pressure Thermoplastic Hoses: Offer excellent resistance to abrasion and chemicals, making them suitable for high-pressure hydraulic applications.

Steel-Reinforced Hydraulic Hoses:

Wire-Braided Hoses: Reinforced with one or two layers of braided steel wire for enhanced strength.

Spiral-Wire Hoses: Reinforced with multiple layers of spiral-wire for increased strength and durability.

Teflon (PTFE) Hydraulic Hoses:

Teflon Core Hoses: Known for their excellent chemical resistance, these hoses are suitable for applications involving corrosive fluids.

Hydraulic Suction Hoses:

Suction and Return Hoses: Designed for applications where hydraulic fluid needs to be drawn from a reservoir back into the system.

Specialty Hydraulic Hoses:

Fire-Resistant Hoses: Designed to withstand exposure to high temperatures and resist flames.

Abrasion-Resistant Hoses: Constructed to resist wear and abrasion in harsh environments.

UV-Resistant Hoses: Suitable for outdoor applications where exposure to sunlight may be a concern.

Compact Hydraulic Hoses:

Compact Spiral Hoses: Offer a smaller bend radius, making them suitable for applications with limited space.

Non-Conductive Hydraulic Hoses:

Non-Conductive Hoses: Designed for applications where electrical conductivity is a concern, providing a safety feature in certain environments.

When selecting a hydraulic hose, it’s crucial to consider factors such as pressure rating, temperature range, flexibility, abrasion resistance, and compatibility with the hydraulic fluid used in the system.

What is Hydraulic Hose Pipe – Factor, Type, Selection criteria, More

Selection criteria of hydraulic hose pipe

Selecting the appropriate hydraulic hose pipe involves considering several critical factors to ensure it meets the specific requirements of the hydraulic system.

Pressure Rating:

Choose a hydraulic hose with a pressure rating that exceeds the maximum operating pressure of the hydraulic system. Consider both continuous and peak pressures.

Temperature Range:

Ensure the hydraulic hose can operate within the temperature range of the hydraulic system. Consider the ambient temperature as well as the temperature of the fluid.

Fluid Compatibility:

Verify that the hydraulic hose is compatible with the type of hydraulic fluid used in the system. Different hoses are designed for use with specific fluids such as oil, water, synthetic fluids, etc.

Size and Dimensions:

Select the appropriate hose size and length to meet the flow rate requirements and fit within the space constraints of the hydraulic system.

Hose Construction:

Consider the construction materials of the hose, including the inner tube, reinforcement layers, and outer cover. Common materials include synthetic rubber, thermoplastics, or metal.

Reinforcement Type:

Choose the right type of reinforcement (e.g., wire braid, spiral, textile) based on the application’s pressure and flexibility requirements.

Flexibility and Bend Radius:

Ensure the hose has the flexibility and bend radius necessary for the specific routing and space limitations of the hydraulic system.

Abrasion Resistance:

If the hose is exposed to abrasive conditions, select a hose with a cover that provides adequate resistance to abrasion and external damage.

Standards Compliance:

Ensure the hydraulic hose complies with industry standards and regulations, such as SAE (Society of Automotive Engineers) or ISO (International Organization for Standardization) standards.

Assembly Compatibility:

Check compatibility with the hose fittings and connectors to ensure a secure and leak-free connection.

Cost Considerations:

Balance the performance requirements with cost considerations. While it’s essential to meet system requirements, cost-effectiveness is also a consideration.

What is Hydraulic Hose Pipe – Factor, Type, Selection criteria, More

Troubleshooting: Hose Failure

Hose failures in hydraulic systems can lead to downtime, reduced efficiency, and even safety hazards. It’s crucial to promptly address and troubleshoot hose failures to prevent further damage. Here are common causes of hydraulic hose failures and troubleshooting tips:

Abrasion or Wear:

Cause: Continuous rubbing against other surfaces or objects.

Troubleshooting:

Use abrasion-resistant hoses or protective covers.

Route hoses away from sharp edges and abrasive surfaces.

Regularly inspect hoses for wear and replace them if necessary.

Fluid Compatibility Issues:

Cause: Incompatibility between the hose material and hydraulic fluid.

Troubleshooting:

Ensure hoses are compatible with the hydraulic fluid used.

Check for signs of chemical degradation, such as swelling or softening.

Replace hoses with materials suitable for the specific hydraulic fluid.

Excessive Pressure:

Cause: Operating the system beyond the rated pressure of the hose.

Troubleshooting:

Use hoses with appropriate pressure ratings.

Install pressure relief valves to prevent overpressurization.

Monitor and maintain pressure levels within recommended limits.

Temperature Extremes:

Cause: Exposure to extreme temperatures, either hot or cold.

Troubleshooting:

Select hoses with temperature ratings suitable for the application.

Insulate hoses or use heat-resistant materials for high-temperature areas.

Ensure hoses are flexible at low temperatures.

Incorrect Hose Installation:

Cause: Improper routing, twisting, or kinking during installation.

Troubleshooting:

Follow manufacturer’s installation guidelines.

Use proper fittings and secure them correctly.

Avoid sharp bends or twists in the hose.

Aging and Fatigue:

Cause: Hoses degrade over time due to exposure to environmental factors and stress.

Troubleshooting:

Implement a regular inspection and replacement schedule.

Store spare hoses in a cool, dark place away from sunlight.

Monitor hoses for signs of aging, such as cracking or hardening.

Contamination:

Cause: Ingress of dirt, debris, or foreign particles into the hydraulic fluid.

Troubleshooting:

Use proper filtration systems to prevent contamination.

Keep hose ends capped when not in use.

Flush and clean the hydraulic system regularly.

Improper Hose Size:

Cause: Using hoses with incorrect inner diameter for the application.

Troubleshooting:

Select hoses with proper size and flow capacity.

Consult manufacturer specifications and guidelines.

Replace hoses with correct size if necessary.

Fitting Issues:

Cause: Incorrect or damaged fittings, improper crimping, or overtightening.

Troubleshooting:

Inspect fittings for damage and replace if necessary.

Use the correct crimping tools and techniques.

Follow torque specifications for tightening fittings.

Vibration and Flexing:

Cause: Excessive vibration or flexing during operation.

Troubleshooting:

Use hoses designed for dynamic applications.

Install vibration dampeners if needed.

Secure hoses properly to minimize movement.

Regular preventive maintenance, including visual inspections, can help identify potential issues before they lead to hose failures. Implementing a comprehensive maintenance schedule and training personnel on proper hydraulic system care are essential for minimizing downtime and ensuring system reliability.

What is Hydraulic Hose Pipe – Factor, Type, Selection criteria, More

What is hydraulic hose pipe made of

Hydraulic hose pipes are typically made of several layers of materials designed to withstand high-pressure hydraulic applications.

The construction of a hydraulic hose includes the following components:

Inner Tube: The inner tube is the core of the hydraulic hose and is in direct contact with the hydraulic fluid. It is usually made of synthetic rubber or thermoplastic materials that are compatible with the specific hydraulic fluids being used.

Reinforcement Layer: The reinforcement layer provides strength and flexibility to the hose. It is typically made of high-tensile steel or synthetic fibers such as aramid or polyester. The reinforcement layer helps the hose withstand the internal pressure generated by hydraulic systems.

Outer Cover: The outer cover protects the hose from external environmental factors, abrasion, and other physical damage. It is made of synthetic rubber, thermoplastic, or a combination of materials that provide resistance to weather, ozone, abrasion, and other external conditions.

Reinforcement and Protective Layers: In addition to the main reinforcement layer, some hydraulic hoses may have additional layers for enhanced strength, flexibility, and protection. These layers can include textile braids, wire helix, or additional covers for added durability.

Advantages and Disadvantages of hydraulic hoses

Advantages of Hydraulic hoses pipe

- Flexible in nature

- High capacity to absorb shocks/vibrations than metal tubes.

- Easy for installation and dismantle.

- They are capable to take high pressure.

Disadvantage of Hydraulic hoses pipe

- Poor abrasion resistance.

- Initial cost is higher.

- They are damaged due to incompatible oil and abrasion.

What is Hydraulic Hose Pipe – Factor, Type, Selection criteria, More

Application of Hydraulic Hoses

Hydraulic hoses play a crucial role in various applications where fluid power is used to transmit energy. These hoses are designed to carry hydraulic fluid under high-pressure conditions to generate mechanical force and motion.

Construction Equipment:

Hydraulic hoses are extensively used in construction machinery such as excavators, bulldozers, loaders, and cranes. They power the hydraulic cylinders responsible for the movement of arms, buckets, and other components.

Material Handling Equipment:

Forklifts, conveyor systems, and other material handling equipment use hydraulic hoses to control the movement of goods, lift loads, and perform other tasks requiring precise and powerful control.

Automotive Industry:

Hydraulic hoses are used in automotive applications, particularly in braking systems. Brake hoses, for example, carry hydraulic fluid to actuate brake calipers, providing the necessary pressure to stop a vehicle.

Mining Operations:

In mining equipment such as drills, loaders, and haul trucks, hydraulic hoses are used to power various components. The robust nature of hydraulic systems makes them suitable for the challenging conditions in mining operations.

Oil and Gas Industry:

Hydraulic systems are employed in oil and gas exploration and production equipment. Hydraulic hoses play a crucial role in the operation of drilling rigs, wellhead control systems, and other equipment.

Aerospace Industry:

Aircraft utilize hydraulic systems for functions such as landing gear retraction, flight control surfaces, and braking systems. High-pressure hydraulic hoses are essential for reliable performance in these critical applications.

Marine Applications:

Hydraulic hoses are used in marine environments for steering systems, winches, and other applications on ships and boats. The resistance of hydraulic systems to corrosion makes them suitable for maritime use.

Manufacturing and Industrial Machinery:

Various industrial machines, including presses, injection molding machines, and hydraulic presses, use hydraulic hoses for power transmission and control.

FAQ’s

What are hydraulic hoses used for?

Hydraulic hoses are primarily used to allow the flow of hydraulic fluid between different components of a hydraulic system.

How often should hydraulic hoses be replaced?

For preventative maintenance, the hydraulic hose should be replaced every one to two years, depending on machine usage. However, periodic inspection is required to avoid failure.

You may also like