Table of Contents

Toyata 3M Model

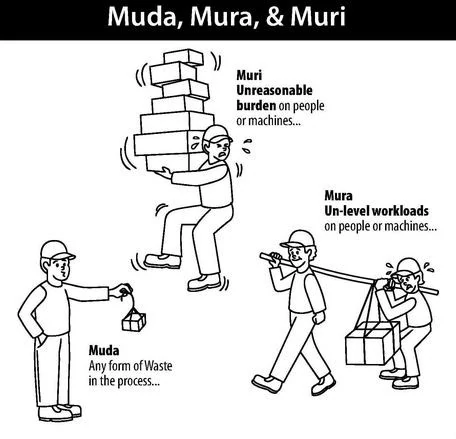

Toyota has built its production system around eliminating three enemies of Lean: Muda (waste), Muri (overload), and Mura (inequality).

Muda is the direct obstacle of the flow. As written below, there are 8 distinctive types of shedding that lead to waiting times and thus longer delivery times in a process.

Simply taking out the molt doesn’t work. There is usually a reason why the mute is there and this reason often has to do with the other two enemies: muri and mura. The three enemies of Lean interrelate and must be addressed simultaneously.

Three Enemies

In office and production processes, three enemies can be found opposing Lean. In office processes, we can find them more often than in production processes. One of the reasons for this is that the production processes are visible. Everyone who walks through a factory can see the inventory becomes Computers, mailboxes, and IT systems conceal processes in the office environment.

Although Lean’s goal is to reduce Lean’s three enemies, it may not be possible to completely eliminate them.

In terms of moving, unless your factory is located next to your customer, there will always be some form of transportation required to get the product to your customer.

We should focus on reducing transportation time and costs as much as we can, but a 100% reduction is not realistic.

The same goes for muri. Machines or people must always put in the extra effort or time to meet customer demand.

There is nothing wrong with this when you can get a large order for additional products or gain a new customer. The problem exists when you expect this from your machines or people all the time, to the point where a machine burns out or a colleague burns out.

Mura cannot always be reduced to 100%, even in the final analysis. When you produce different products, they may require different materials, a different way of working, or even different lead times.

This is even more true in project work, where every project is different, or in the financial world, where a financial report is due at the end of each month.

The following three articles explain in more detail how we can find and remove the three enemies of Lean from our processes, here is a brief description of what you can expect:

MUDA

Toyota defines seven types of waste as unused skills among the eight that can be identified. These are: Defects, Overproduction, Waiting, Unused Talent, Transportation, Inventories, Movement and Excess paperwork.

As a mnemonic device, the first letters of these residues form the acronym DOWNTIME.

There are numerous tools available to identify and remove waste from your process, including Poke Yoke, Kanban, Takt Time, SMED, and One Piece Flow.

However, the most common tool that helps improve productivity by eliminating the 7 wastes is 5S. In the article “How to Find Muda (waste) in Your Process,” you describe and link the tools to systematically eliminate each waste type.

Muda means futility uselessness waste, although more broadly it refers to the seven common types of waste seen in business.

- Defects in the final product

- Time lost due to waiting processes

- Non-essential movement

- Excess inventory of materials or equipment

- Excess production

- Redundant processes

- Unnecessary transportation or handling of materials or products

MURI

Overhead can result from Mura and removing too much Muda (waste) from the process. When operators or machines use more than 100% to complete their task, they are working too hard or are overtaxed.

This means breakdowns when it comes to machines and absenteeism when it comes to employees. We can implement preventive and autonomous maintenance to optimize the use of the machines and ensure they work properly.

To prevent employee overwork, safety must be at the center of all process designs and standard work initiatives. For more information on Muri, go directly to the article: Finding Muri (overload) in your process.

MURA

The fluctuation of customer demand, the process times per product, and the variation of cycle times for different operators can result in gaps. In low volume, high product variation production environments, flexibility is more important than in high volume, low product variation environments. Muda’s reduction of Mura makes its existence less likely, decreasing Muda’s chances.

FAQ

What is Muda Mura and muri?

Muda, mura and muri are three types of useless actions that negatively affect workflow, productivity and ultimately customer satisfaction.

What are the 3 M’s of Lean?

Muda, Muri and Mura

Muda, Muri, and Mura are called the three M’s. Together they form a dissonant triad. To create a sustainable lean process, we must remove the three M’s.

What are the 7 types of Muda?

The 7 forms of muda

Waste of overproduction (largest waste)

Waste of available time (waiting)

transportation waste.

Waste from the processing itself.

Waste of stock at hand.

Movement waste.

Waste from the manufacture of defective products.

What is this kaizen?

Kaizen is a Japanese business philosophy that focuses on gradually improving productivity by involving all employees and making the work environment more efficient. Kaizen translates to “change for the better” or “continuous improvement.”

You may also like