When oil acts on both side of piston i.e. on face side for forward movement and piston rod side for return movement. It is known as double acting hydraulic cylinder.

A double-acting hydraulic cylinder is a type of hydraulic actuator that can generate force in both the extension and retraction strokes. It consists of a cylindrical barrel, a piston, and a rod, along with seals to prevent fluid leakage.

Table of Contents

How a double-acting hydraulic cylinder typically operates

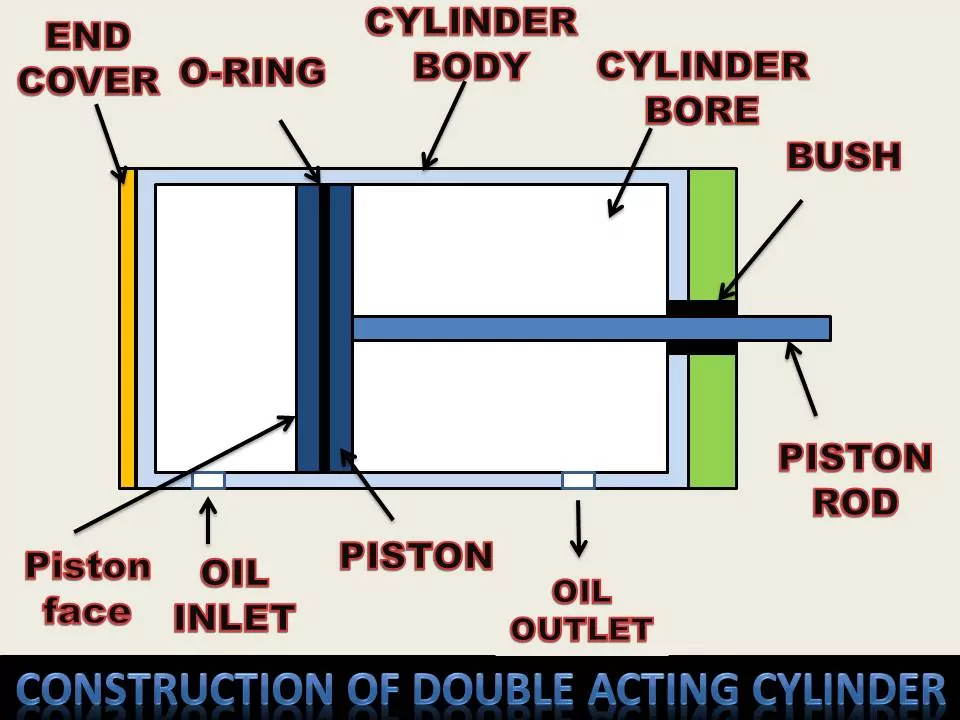

Construction: A double-acting hydraulic cylinder consists of a cylindrical barrel with an enclosed chamber and two ports one for the extension stroke and the other for the retraction stroke. The piston divides the chamber into two areas one on each side of the piston.

Extension stroke: Pressurized hydraulic fluid is supplied to the extension port of the cylinder. The hydraulic pressure acts on one side of the piston, pushing it in the direction of the extension stroke. This creates a force that extends the rod outward from the cylinder.

Retraction stroke: To retract the rod, hydraulic fluid is supplied to the retraction port, applying pressure on the opposite side of the piston. The pressure differential causes the piston to move in the opposite direction, pulling the rod back into the cylinder.

Sealing and fluid control: Double-acting cylinders have seals on both ends of the piston to prevent hydraulic fluid from leaking between the two sides. These seals ensure the efficiency and reliability of the cylinder by maintaining proper pressure differentials.

Construction

Cylinder body – It is seamless tube of Al alloy or steel with chrome plated to provide better corrosion and scratch resistance, stainless steel, cast iron also used for body.

Piston and piston rod – The pistons are made of aluminium alloy castings. They are fitted precisely in the cylinder bore with the help of piston seals. Piston rod is attached to the piston and made of steel bar.

Piston seals – It is provided for leak proof assembly between cylinder bore and piston.

Bushing – Bush are provided for smooth movement of piston rod and for reducing leakage of oil. They are made of brass, bronze, babbit metal and press fitted to cap end.

End covers – The end covers are provided at the front end as well as at rear end.

Working

When pressurised oil enters through inlet A from face side of piston, it pushes the piston to the right hand side to complete forward stroke

while the oil on the rod side is delivered through the outlet to the tank through the outlet B.

When pressurised oil enters through inlet B from piston rod side. It moves the piston to the left hand side and completes the return stroke.

The oil from the face side is drained out through outlet A to the tank.

It gives to and fro (reciprocation) movement of piston.

Cushioning of double acting cylinder

Cushioning of cylinders means gradual deceleration of the piston near the end of its stroke. It means slowing down the speed of the piston near the end of cylinder body.

It is very helpful to reduce shock or impact of load on the cylinder end covers specially when a heavy load is connected to the rod or the cylinder and is working at very high speed.

The cushion assembly is around 25mm long for a standard cylinder. It consists of a small passage to allow entrapped oil to the port with a cushion needle with an check valve to allow free flow of oil during reverse flow of oil during reverse start of piston travel.

The end of the cushion nose is tapered in order to enter more easily into the cushion chamber.

The fluid is normally leaves through the outlet port directly, but when cushioning boss enters the recess, the fluid around the piston is trapped.

The only way the fluid can escape is through the secondary path which is restricted by needle valve.

The needle valve is adjusted so that the piston is slowed up over the last part of its stroke by a pressure build up in the fluid escaping past the needle valve.

Symbol

Applications Double Acting Hydraulic Cylinder

Double-acting hydraulic cylinders are a common component in various industrial and mobile hydraulic systems. They are designed to perform work in both directions (extend and retract) and are crucial in applications where precise control, high force, and flexibility are required.

Here are some common applications of double-acting hydraulic cylinders:

It is used in machine tool like shaper machine, table movement of milling, hydraulic press machines etc.

Construction Equipment: Double-acting hydraulic cylinders are extensively used in construction machinery, such as bulldozers, excavators, backhoes, and loaders. They are employed for tasks like lifting heavy loads, extending and retracting booms and buckets, and controlling the movement of various components.

Material Handling: Hydraulic cylinders are utilized in various material handling applications, such as forklifts, conveyor systems, and overhead cranes. They can be used to lift, tilt, and move heavy loads with precision.

Manufacturing Machinery: In manufacturing, hydraulic cylinders are used in machinery like metal stamping presses, injection molding machines, and hydraulic presses for forming, shaping, and assembling products.

Automotive Industry: Hydraulic cylinders play a role in automotive applications, including car lifts for servicing and maintenance, as well as in the operation of dump trucks and garbage trucks.

Oil and Gas Industry: In the oil and gas sector, hydraulic cylinders are employed in drilling rigs, wellhead control systems, and pipeline maintenance equipment for tasks like valve actuation and pressure control.

Civil Engineering: Double-acting hydraulic cylinders are used in civil engineering applications, such as bridge construction and maintenance, where they are employed for lifting and positioning heavy bridge sections.

Railroad Maintenance: Hydraulic cylinders are used in railway maintenance equipment to perform tasks like lifting and positioning rail tracks and controlling switches.

Hydraulic Presses: Hydraulic presses, used in various industries, rely on double-acting cylinders to generate force for applications like metal forming, powder compacting, and plastic molding.

Advantages and Disadvantages

Double-acting hydraulic cylinders are widely used in various applications where bidirectional force and precise control are required. Here are the advantages and disadvantages of double-acting hydraulic cylinders:

Advantages

Bidirectional force: Double-acting cylinders can exert force in both directions, allowing for pushing and pulling actions. This flexibility enables a wider range of applications compared to single-acting cylinders, which can only exert force in one direction.

Precise control: Double-acting cylinders provide more precise control over the movement and positioning of loads. By applying hydraulic pressure to either side of the piston, the speed and direction of movement can be precisely regulated, allowing for fine adjustments and accurate positioning.

Faster operation: Double-acting cylinders typically operate faster than single-acting cylinders. Hydraulic pressure can be applied to either side of the piston, enabling faster extension and retraction speeds, which can improve overall productivity in time-sensitive applications.

Increased efficiency: Double-acting cylinders can contribute to increased efficiency in hydraulic systems. The bidirectional force capability allows for a more balanced load distribution, reducing the strain on individual components and optimizing energy usage.

Disadvantages

Complexity: Double-acting cylinders are more complex in design compared to single-acting cylinders. They require additional hydraulic connections and control systems to regulate pressure on both sides of the piston. This complexity can increase the cost and maintenance requirements of the hydraulic system.

Higher initial cost: Double-acting cylinders tend to have a higher initial cost compared to single-acting cylinders due to their more intricate design and additional components. However, their enhanced functionality and performance capabilities may justify the higher investment in many applications.

Increased risk of leakage: With double-acting cylinders, there is a higher risk of hydraulic fluid leakage since both sides of the piston require sealing. Proper maintenance and regular inspection of seals and connections are necessary to prevent leaks and ensure optimal performance.

Additional space requirements: Double-acting cylinders typically require more space for installation compared to single-acting cylinders due to their bidirectional force capability. The presence of hydraulic connections and control mechanisms adds to the overall footprint of the cylinder.

FAQ

How many inlets to double acting cylinder ?

A Double acting hydraulic cylinder has two oil inlets for hydraulic oil at both the ends of the chambers.

On passing hydraulic oil from one end, piston moves forward and pushes the oil out from the other end and vice versa.

So each end of the cylinder acts as both inlet and outlet for the hydraulic oil.

What is a double acting hydraulic cylinder?

When oil acts on both side of piston i.e. on face side for forward movement and piston rod side for return movement. It is known as double acting cylinder.

Where double acting cylinder used for?

Double-acting cylinders are typically used in all applications where the thrusts and stroke lengths required are in excess of those available from single-acting cylinders.

Why Is Cushioning Necessary?

Cushioning is needed to lower the speed of the cylinder before it reaches the end cap. Lowering the speed of the piston helps reduce stress on the components within the cylinder. It also lessens vibration conveyed to the other parts of the machine.

How does a cushioned hydraulic cylinder work?

How do hydraulic cylinder cushioning decelerate cylinder? As mentioned, the cylinder retracts when the fluid flows outwards and when the piston rod approaches the end cap. In a cushioned hydraulic cylinder, the cushion plunger will enter into the cushion cavity when it approaches the end cap.

You may also like